Rising bunker costs and lagging vessel speeds directly impact your bottom line. Every knot lost and every extra ton of fuel burned erodes profit margins, increases engine strain, and negatively affects your CII rating. The primary culprit is often overlooked: marine biofouling on your vessel’s propeller. A rough propeller surface forces your engine to work harder, consuming more fuel just to maintain chartered speed. This is where a targeted, expert service like professional underwater propeller polishing becomes not just a maintenance task, but a critical investment in your operational efficiency.

This comprehensive guide provides the essential information that ship owners and charterers require. We will detail exactly how a class-approved propeller polish restores hydrodynamic performance, delivering measurable fuel savings and a clear return on investment. Discover the process, the technology involved, and how to minimize service time without dry-docking-ensuring your vessel maintains peak performance and navigates critical transits like the Panama Canal without costly delays. Put our expertise to work for your fleet.

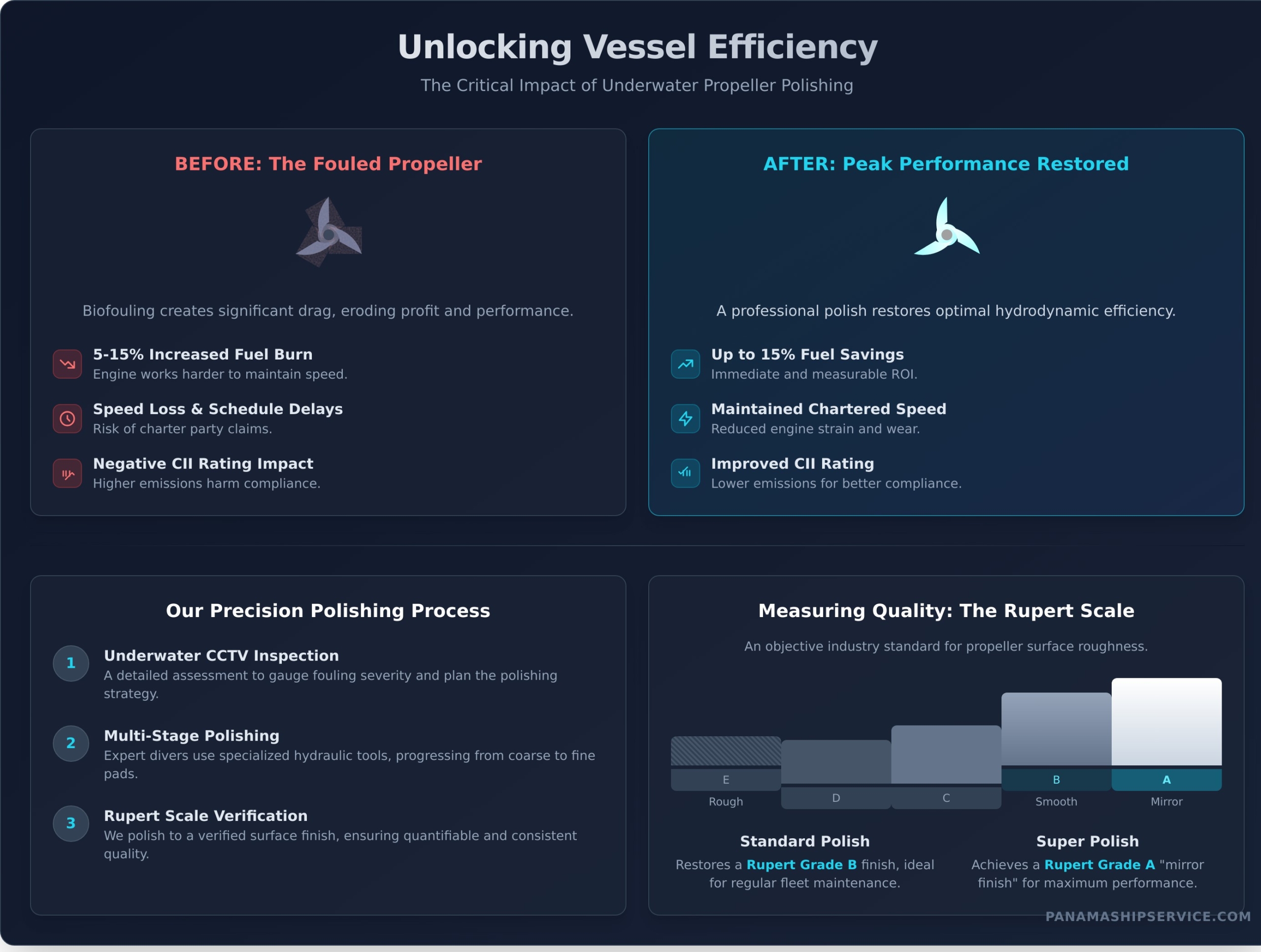

The Hidden Costs of a Rough Propeller: Why Polishing is Essential

A vessel’s propeller is its engine of propulsion, converting engine power into thrust with maximum efficiency. This efficiency, however, is entirely dependent on a clean, smooth surface. Any deviation from a hydrodynamically perfect blade surface introduces drag and turbulence, directly increasing a vessel’s operational expenditure (OPEX). The primary enemy of this performance is marine growth, a persistent challenge that makes regular maintenance a critical, cost-saving activity.

How Biofouling Degrades Vessel Performance

The accumulation of marine organisms on submerged surfaces, a process known as biofouling, is the root cause of propeller roughness. This begins with a simple slime layer and can quickly escalate to hard fouling like barnacles and tubeworms. This growth disrupts the smooth flow of water over the blades, creating significant drag. A rough surface also exacerbates cavitation-the formation and collapse of vapor bubbles-which can erode the propeller material itself. The immediate operational impact is a loss of speed, leading to schedule delays and potential charter party claims.

The Direct Link Between Roughness and Fuel Consumption

A fouled propeller forces the main engine to work harder to achieve the same speed, functioning much like a car driving with the handbrake slightly engaged. Industry studies consistently show that even microscopic roughness can have an outsized impact on fuel efficiency. It is common for moderate to heavy propeller fouling to cause a 5-15% increase in fuel consumption. This waste of fuel translates directly into lost profit. An effective program of underwater propeller polishing is the most direct solution to reclaim this lost efficiency.

Beyond Fuel: Engine Strain and Emission Concerns

The consequences of a rough propeller extend beyond the fuel tank. The increased load places significant strain on the main engine and the entire shaft system, accelerating wear and tear and leading to higher maintenance costs over time. Furthermore, burning more fuel directly results in higher emissions of CO2, SOx, and NOx. In an era of tightening environmental regulations, managing these emissions is critical for compliance with mandates like the IMO’s Carbon Intensity Indicator (CII), making routine underwater propeller polishing an essential part of responsible vessel management.

The Underwater Polishing Process: A Step-by-Step Technical Overview

Effective underwater propeller polishing is a highly skilled technical service, not simple cleaning. The objective is to restore a propeller’s surface to a near-new, hydrodynamically efficient condition, directly impacting your vessel’s performance and fuel consumption. This meticulous process is executed by qualified dive teams using specialized equipment to achieve quantifiable results without altering the propeller’s critical geometry.

From Inspection to Execution: How Divers Work

Every project begins with a detailed underwater inspection, typically using high-resolution CCTV cameras. This initial assessment allows our team to accurately gauge the type and severity of marine fouling and identify any pre-existing damage. Based on this data, our expert divers select the appropriate tools and approach. The polishing itself is a multi-stage process utilizing hydraulic-powered rotary tools. Divers begin with coarser abrasive pads to remove heavy biofouling like barnacles and tubeworms, then progressively switch to finer discs to eliminate all roughness, ensuring a smooth finish. The diver’s skill is paramount to prevent rounding of blade edges or altering the propeller’s precise design.

Measuring Success: Understanding the Rupert Scale

To provide an objective measure of quality, the maritime industry uses the Rupert Scale for surface roughness comparison. This standardized scale ensures that ship owners receive a verifiable and consistent result. A comparator gauge is used to compare the propeller surface against these grades:

- Grade A: Mirror-smooth finish, the optimal condition.

- Grade B: Smooth finish, typical of a new propeller.

- Grades C-E: Progressively rougher surfaces with significant fouling.

While a new propeller is typically delivered at Grade B, a professional polish can achieve Grade A. This commitment to objective measurement is a key component of the official propeller polishing guidance from maritime authorities like the IMO. Our goal is always to deliver a finish that meets or exceeds industry standards.

Standard vs. Super Polishing: Which is Right for Your Vessel?

We offer two primary levels of service to meet diverse operational needs. Standard Polishing is the most common and cost-effective solution, focused on removing all visible marine growth and restoring the surface to a smooth condition (typically Rupert Grade B). For vessels requiring maximum performance, we offer Super Polishing. This more intensive service aims for a Rupert Grade A “mirror finish,” minimizing surface friction to the absolute lowest level possible. A super polish is often recommended for high-performance vessels or those on tight schedules where every fraction of a knot counts. For most of the global fleet, a program of regular, standard underwater propeller polishing provides the most efficient and balanced return on investment.

Quantifying the ROI: The Tangible Benefits of a Smooth Propeller

While the technical process is precise, the results that matter to fleet managers are measured in dollars and knots. A fouled propeller creates significant drag, increasing fuel consumption and operational costs. The economic impacts of biofouling are well-documented, turning a minor maintenance task into a major financial liability if ignored. Professional underwater propeller polishing is not an expense; it is a high-return investment in vessel efficiency and performance.

Calculating Fuel Savings: A Practical Example

To understand the direct financial return, consider a common scenario for a mid-sized vessel. Applying a conservative fuel saving percentage after a thorough polishing reveals a rapid ROI.

- Daily Fuel Consumption: 40 metric tons (MT) at $650/MT = $26,000

- Conservative Fuel Saving (Post-Polishing): 5%

- Daily Savings in USD: $26,000 x 0.05 = $1,300 per day

- Monthly Savings in USD: $1,300 x 30 days = $39,000 per month

The cost of the polishing service is typically recovered within a few days, delivering pure profit for the remainder of the voyage and protecting your operational budget.

Performance Gains: Increased Speed and Reduced Vibration

Beyond fuel, a smooth propeller directly impacts vessel performance. Restoring the propeller to its optimal hydrodynamic profile can increase speed by 0.5 to 1 knot, improving schedule integrity and operational flexibility. Furthermore, a properly balanced and clean propeller significantly reduces cavitation, noise, and vibration. This enhances crew comfort and reduces long-term stress on the shaft, seals, and engine components, preventing more costly repairs down the line.

Documentation and Reporting: Proving the Value

Value delivered must be value proven. Every service we conduct is supported by comprehensive documentation to verify the quality and effectiveness of the work. Our standard report provides objective proof, including:

- High-resolution before-and-after photographs.

- Underwater video of the entire polishing process.

- Rupert Scale (Grade A-E) readings to objectively measure surface roughness.

This documentation is vital for your maintenance records and for satisfying class society requirements. See examples of our detailed service reports.

Choosing Your Service Partner at the Panama Canal

Selecting the right team for in-water maintenance is a critical operational decision. At the Panama Canal, a global maritime chokepoint, this choice directly impacts your vessel’s schedule, budget, and performance. The waiting period for Canal transit presents a unique, strategic window to perform essential services without deviating from your route. Executing this opportunity requires a partner with proven expertise, unwavering safety standards, and deep local knowledge.

Why Panama is the Ideal Location for Propeller Polishing

Vessels frequently wait at anchor on the Pacific or Atlantic side before their scheduled transit. This operational pause is the perfect time for an underwater propeller polishing service. Performing maintenance here eliminates the need for costly route deviations and avoids dedicated downtime at the next port of call. Panama’s strategic position has fostered a competitive market of skilled, certified providers, ensuring you receive efficient and high-quality service.

Essential Qualifications for a Dive Team

When vetting a service provider, technical proficiency and safety are non-negotiable. Your partner must be able to deliver high-quality results under tight deadlines. Before engaging any team, demand proof of the following essential qualifications:

- Class Society Certifications: Approval from major classification societies like ABS, DNV, and Lloyd’s Register is a primary indicator of quality and adherence to global standards.

- Verified Safety & Insurance: A robust safety management system and comprehensive insurance coverage are critical to protect your crew, vessel, and assets.

- Proven Track Record: Ask for recent case studies or references from vessels with similar specifications to validate their experience and performance.

- 24/7 Availability: The shipping industry operates around the clock. Your partner must be available for emergency calls and flexible scheduling to meet your transit window.

The Panama Ship Service Advantage

Panama Ship Service is your trusted partner at the Panama Canal, built to meet and exceed these exacting standards. Our dive teams are fully certified by all major class societies and operate under the strictest safety protocols. We are not just technicians; we are local experts who manage all coordination with port and Canal authorities, ensuring seamless, regulation-compliant operations.

We provide a comprehensive, one-stop-shop solution for all your in-water needs, from hull cleaning and inspections to expert underwater propeller polishing. We understand that timing is everything. Our teams are organized for rapid response to minimize expenses and maximize your vessel’s efficiency for the journey ahead. Put your transit in our hands.

Get a competitive quote for your next Panama transit.

Maximize Efficiency with an Expert Partner at the Panama Canal

In the high-stakes world of maritime shipping, operational efficiency is paramount. As this guide has shown, a smooth, professionally polished propeller is not an expense-it is a powerful investment in fuel economy and profitability. By addressing surface roughness, you directly combat increased fuel consumption, unlocking a quantifiable return on investment and ensuring your vessel performs at its peak. The critical factor is choosing a service partner with the technical expertise to deliver results without causing delays.

When your vessel requires expert underwater propeller polishing at the Panama Canal, Panama Ship Service is your trusted, solution-focused partner. Our 24/7 rapid response teams provide class-approved services recognized by DNV, ABS, and Lloyd’s Register, ensuring compliance and quality. With unmatched expertise in Panama Canal and port operations, we deliver the efficient, cost-conscious solutions required to protect your schedule and your bottom line.

Don’t let propeller drag compromise your voyage. Request a quote for class-approved propeller polishing at the Panama Canal today.

Frequently Asked Questions

How often should a ship’s propeller be polished?

The optimal frequency for underwater propeller polishing depends on the vessel’s operational profile, including trading routes and idle periods. As a general guideline, we recommend polishing every 6 to 12 months to maintain peak fuel efficiency. Regular underwater inspections can determine the precise schedule based on the level of marine growth and surface roughness. Proactive polishing is a cost-effective measure to prevent significant performance loss and reduce operational expenses.

Can propeller polishing damage the propeller blades?

When executed by certified technicians using specialized hydraulic equipment, propeller polishing is a safe procedure that does not damage the blades. The process is designed to remove marine fouling and restore the surface to its ideal smoothness (Rupert Scale A or B) without altering the propeller’s geometry. However, improper techniques by unqualified personnel can cause damage. This is why selecting a trusted, expert service provider is critical to protect your asset.

What is the difference between propeller cleaning and propeller polishing?

Propeller cleaning is the initial stage, focused on removing marine biofouling like algae and barnacles. While cleaning improves hydrodynamic performance, propeller polishing is a more meticulous process. Polishing goes further by using finer abrasive pads to smooth the blade surface to a specific, near-mirror finish. This second step is essential for minimizing surface roughness, which directly translates to maximum fuel efficiency and reduced emissions for your vessel.

How long does a typical underwater propeller polishing service take?

The duration of a typical service is highly efficient to minimize vessel downtime. For a standard-sized vessel, the entire process can often be completed within 2 to 5 hours. This timeframe depends on factors such as the propeller’s size, the extent of marine fouling, and the number of blades. Our qualified dive teams are equipped to perform the work swiftly and safely, ensuring your vessel can return to its operational schedule with minimal delay.

Is propeller polishing environmentally friendly?

Yes, professional propeller polishing is an environmentally responsible maintenance activity. The process uses water-lubricated hydraulic tools and abrasive pads without releasing harmful chemicals into the marine environment. More importantly, the primary benefit of polishing is a significant reduction in fuel consumption. This directly leads to lower greenhouse gas emissions (CO2, SOx, NOx), contributing positively to the vessel’s environmental performance and regulatory compliance.

Can you perform polishing on all types of propellers, including CPP and FPP?

Absolutely. Our expert dive teams are fully trained and equipped to perform high-quality polishing on all major propeller types. This includes both Fixed Pitch Propellers (FPP) and the more complex Controllable Pitch Propellers (CPP). The techniques and equipment are adapted to suit the specific design and material of the propeller, ensuring a uniform, high-grade finish across all blades. We deliver consistent, reliable results regardless of your vessel’s propulsion system.