In the high-stakes world of maritime logistics, controlling operational expenditure (OpEx) is not just a goal-it is a critical requirement for survival. Volatile fuel prices erode your margins, while unscheduled repairs and inefficient port calls create costly delays that ripple through your entire supply chain. The pressure to maintain profitability without compromising safety or compliance is immense. For fleet managers, the central challenge is clear: how to reduce ship operating costs effectively and sustainably in this demanding environment.

This 2025 guide provides the expert solutions you need. We move beyond theory to deliver actionable, proven strategies for mastering your vessel OpEx. You will discover how to implement advanced fuel optimization techniques, build a proactive maintenance schedule that prevents costly downtime, streamline crew management for maximum efficiency, and execute smart port calls that save both time and money. Our focus is on providing the qualified, cost-conscious solutions that lead to improved vessel reliability and secure your long-term profitability.

Understanding the Anatomy of Ship Operating Costs (OpEx)

To effectively control vessel expenses, ship owners and charterers must first have a detailed understanding of where every dollar is allocated. Ship Operating Expenses, or OpEx, are the daily costs incurred to keep a vessel safe, compliant, and operational. Mastering these figures is the foundational step in any successful strategy for how to reduce ship operating costs. A comprehensive grasp of Understanding Ship Operating Costs (OpEx) reveals that these expenses are not monolithic; they are a composite of several key areas, each demanding expert management.

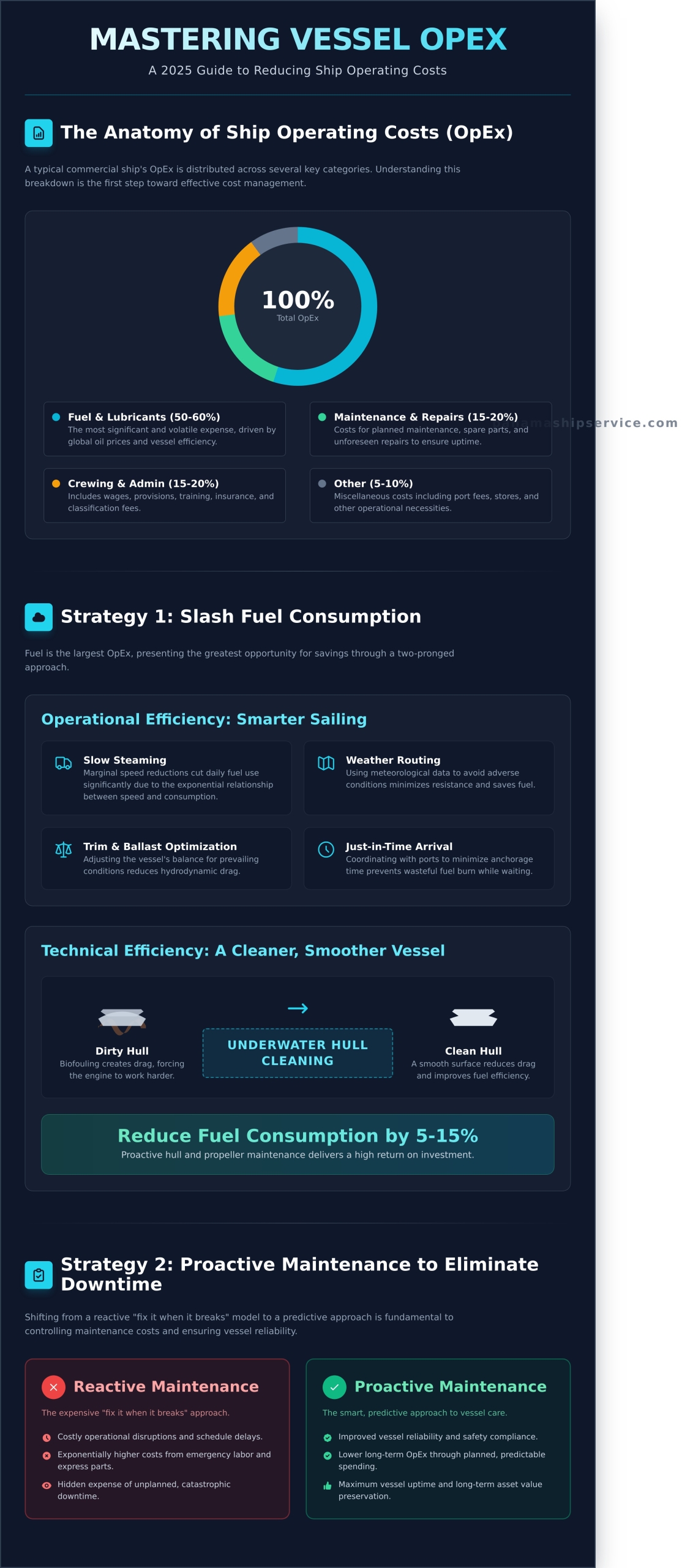

While the exact percentages vary by vessel type, age, and trade route, a typical commercial ship’s OpEx is distributed across three primary categories. This breakdown provides a clear roadmap for identifying areas ripe for efficiency improvements.

Visual Aid: Typical Breakdown of Ship OpEx

[A pie chart would be placed here illustrating the following approximate percentages: Fuel & Lubricants (50-60%), Maintenance & Repairs (15-20%), Crewing & Admin (15-20%), and Other (5-10%).]

Fuel & Lubricants: The Largest Expense

Bunker costs are the most significant and volatile component, often accounting for 50-60% of total OpEx. This expense is directly influenced by volatile global oil prices, engine performance, and the vessel’s hydrodynamic efficiency, which is impacted by hull and propeller condition. To mitigate price risk, carriers often use Bunker Adjustment Factors (BAFs) to pass on fluctuations to shippers, but direct cost control remains a top priority for operators.

Maintenance & Repairs: The Cost of Uptime

This category includes all costs associated with keeping the vessel technically sound, from planned maintenance schedules and spare parts inventory to unforeseen emergency repairs. A critical, often hidden, expense here is the cost of unplanned downtime. Proactive maintenance strategies are essential. Key activities include major overhauls during scheduled dry-docking (out-of-water) and more routine in-water repairs that can be performed while the vessel is afloat, minimizing service interruptions.

Crewing & Administrative Costs

The final major segment covers both human and regulatory expenses. A well-managed approach to these costs is a key part of how to reduce ship operating costs without compromising safety or quality. These include:

- Crewing: Wages, provisions, medical care, training, and repatriation for the onboard team.

- Administrative: Hull & Machinery (H&M) and Protection & Indemnity (P&I) insurance, classification society fees, certifications, and shoreside management fees.

It is crucial to recognize that a competent and well-trained crew is a primary driver of efficiency, directly impacting fuel consumption, maintenance quality, and overall vessel safety.

Strategy 1: Slashing Fuel Consumption with Technical and Operational Measures

For any ship owner or charterer, fuel represents the single largest and most volatile operating expenditure. This volatility, however, also presents the most significant opportunity for cost reduction. The most effective strategies for how to reduce ship operating costs begin by targeting fuel consumption through a two-pronged approach: optimizing how the vessel is operated and maintaining its physical condition. With increasing regulatory pressure from measures like the Energy Efficiency Existing Ship Index (EEXI), these improvements are no longer just cost-saving measures-they are essential for compliance.

Operational Efficiency: Smarter Sailing

How your crew operates the vessel day-to-day has a direct and immediate impact on the fuel bill. Implementing smart sailing practices is a cost-effective way to achieve substantial savings. Key operational tactics include:

- Slow Steaming: The relationship between speed and fuel consumption is exponential. Even a marginal reduction in speed can cut daily fuel use significantly.

- Weather Routing: Utilizing advanced meteorological data to plot routes that avoid adverse currents, high winds, and rough seas minimizes resistance and saves fuel.

- Trim & Ballast Optimization: Adjusting the vessel’s trim and ballast for prevailing conditions reduces hydrodynamic drag, allowing the ship to move through the water with less effort.

- Just-in-Time Arrival: Coordinating with port authorities to minimize anchorage time prevents wasteful fuel burn while waiting for a berth.

Technical Efficiency: A Cleaner, Smoother Vessel

A vessel’s physical condition is a critical factor in its fuel efficiency. Over time, the buildup of marine biofouling on the hull and propeller creates significant drag, forcing the main engine to work harder to maintain speed. This is a direct drain on your fuel budget. A clean, smooth underwater surface is paramount for performance, and proactive maintenance delivers a high ROI. Regular underwater hull cleaning, for instance, is proven to reduce fuel consumption by 5-15%.

Similarly, a propeller with even minor surface roughness loses significant efficiency. Regular propeller polishing restores its design performance, ensuring maximum thrust from every liter of fuel burned. These technical maintenance tasks are just a few of the 101 actionable cost-saving tips that savvy operators use to control expenses. Ultimately, a focus on technical efficiency is a cornerstone of any serious plan for how to reduce ship operating costs.

Optimize your vessel’s efficiency with expert underwater services at the Panama Canal.

Strategy 2: Proactive Maintenance to Eliminate Costly Downtime

In the high-stakes maritime industry, the “fix it when it breaks” approach is a direct path to budget overruns. Reactive, unscheduled repairs are exponentially more expensive than planned maintenance due to emergency labor rates, express parts shipping, and severe operational disruptions. An effective strategy for how to reduce ship operating costs is to shift to a predictive model. A reliable vessel avoids costly off-hire periods, port state control detentions, and charter party disputes, protecting both your revenue and your reputation.

Implementing a Planned Maintenance System (PMS)

A Planned Maintenance System (PMS) is the foundation of operational reliability. This software-based system schedules all critical maintenance tasks based on equipment running hours or specific calendar intervals, as mandated by manufacturers and classification societies. A properly implemented PMS ensures your vessel remains compliant, prevents warranty invalidation, and transforms maintenance from a reactive expense into a predictable, manageable operational cost. It is an essential tool for any cost-conscious operator.

Condition-Based Monitoring (CBM)

Condition-Based Monitoring (CBM) elevates proactive maintenance by using real-time data to predict failures before they occur. Instead of relying solely on schedules, CBM uses advanced diagnostics to assess the actual health of your machinery. This allows for just-in-time interventions, minimizing unnecessary work and maximizing component life. Key CBM techniques include:

- Vibration Analysis: Detects imbalances or misalignments in rotating machinery like pumps and engines.

- Oil Analysis: Identifies wear particles and fluid contamination, indicating internal component degradation.

- Thermal Imaging: Pinpoints electrical faults or overheating mechanical parts before they fail.

By leveraging CBM, you can order parts and schedule specialist labor well in advance, turning a potential crisis into a routine, cost-controlled task.

The Role of On-Voyage and Port Repairs

A comprehensive maintenance strategy distinguishes between minor repairs the crew can handle at sea and major work requiring shoreside specialists. Efficiently leveraging port calls for scheduled and preventative repairs is critical to minimizing downtime. Partnering with a single, trusted provider for all port-based repairs eliminates coordination headaches and ensures consistent, high-quality work. This streamlined approach guarantees your vessel gets the expert attention it needs without delay. Handle all your mechanical and steel repairs efficiently with our 24/7 team.

Strategy 3: Optimizing Crew, Stores, and Administrative Expenses

While fuel consumption often dominates discussions about vessel OPEX, significant savings are found in the expert management of crew, stores, and administrative functions. These costs accumulate steadily and can erode profitability if not controlled. For ship owners and charterers focused on how to reduce ship operating costs, efficiency in these areas is achieved through superior planning, strategic supplier relationships, and streamlined administrative processes.

A well-managed vessel is not just about the engine room; it is about the entire support ecosystem performing at peak efficiency.

Effective Crew Management

Your crew is your most valuable operational asset. Investing in their competence directly reduces long-term costs. Continuous training on new equipment and evolving regulations prevents costly errors and improves performance. Furthermore, minimizing crew turnover is critical, as the recurring expenses of recruitment, certification, and onboarding are substantial. Fostering a culture of cost-consciousness onboard empowers crew members to identify and implement efficiencies in their daily tasks, from energy consumption to waste management.

Strategic Sourcing of Stores and Spares

Last-minute and emergency deliveries of stores and spare parts are a major source of unnecessary expense. The solution is proactive inventory management and strategic sourcing. A key component of learning how to reduce ship operating costs is partnering with a reliable ship chandler who has a strong local supply network. This ensures competitive pricing and timely delivery, avoiding port delays. An effective inventory system prevents both overstocking-which ties up capital-and running out of critical parts, which can lead to operational standstills.

Streamlining Regulatory Compliance

The cost of non-compliance is severe: fines, detentions, and reputational damage can dwarf planned operational expenses. Efficiently managing regulatory requirements is non-negotiable. This includes:

- MARPOL Disposal: Handling sludge, slops, and garbage according to strict international standards requires a qualified and certified partner to avoid penalties.

- Marine Surveys: Using regular surveys to verify vessel condition, draft, and bunker levels ensures you are compliant and only paying for what you receive.

Consolidating these essential functions with a single, trusted agency simplifies administration and ensures expert oversight. A partner like Panama Ship Service acts as your expert on the ground, ensuring every compliance detail is managed efficiently and professionally.

Strategy 4: Using Port Calls as a Cost-Saving Opportunity

Ship owners and charterers often view port calls as unavoidable expenses-a necessary stop that adds to the bottom line. However, a strategic shift in perspective can transform these stops, particularly at critical chokepoints like the Panama Canal, into significant cost-saving opportunities. Instead of a logistical hurdle, a port call becomes a chance to perform essential services efficiently, minimizing downtime and consolidating expenses.

The key is to move away from fragmented, multi-vendor management. Coordinating with numerous agents for different services creates logistical complexity, increases agency fees, and risks costly delays. An integrated approach is the most effective solution for how to reduce ship operating costs during these crucial transit windows.

The ‘One-Stop-Shop’ Advantage

Engaging a single, expert service provider at the Panama Canal offers a decisive advantage. This model streamlines all operational and technical needs into one seamless process. The benefits are immediate and tangible:

- Consolidated Services: Simultaneously coordinate vital tasks such as hull cleaning, bunker surveys, MARPOL disposals, provisions, and minor repairs.

- Simplified Logistics: A single point of contact eliminates the need to manage multiple agents, reducing communication overhead and minimizing the risk of errors.

- Guaranteed Efficiency: Ensure all necessary services are completed within the vessel’s transit window, preventing delays that disrupt schedules and increase operational costs.

Case Study: A Vessel Transiting the Panama Canal

Consider a vessel that requires hull cleaning for fuel efficiency, a minor engine repair, and fresh provisions during its canal transit. The inefficient approach involves contracting three separate vendors. This results in three sets of logistics, three invoices, and a high probability of one service delaying another. The efficient approach is to use a single, trusted partner to coordinate all three tasks. This ensures technicians, divers, and suppliers work in a synchronized manner, maximizing productivity while the vessel is anchored. This is a practical example of how to reduce ship operating costs by leveraging expert coordination. Let us show you how to minimize expenses on your next Panama Canal transit.

Your Partner in Driving Down Ship Operating Costs

As we’ve explored, the answer to how to reduce ship operating costs in 2025 lies in a multi-faceted strategy, not a single fix. By implementing proactive maintenance schedules to eliminate costly downtime and leveraging every port call as a strategic savings opportunity, you can take decisive control of your fleet’s financial performance.

Putting these strategies into practice requires a trusted, expert partner on the ground. For over 20 years, Panama Ship Service has served as the operational arm for fleets transiting the Panama Canal. Our proven track record in minimizing vessel expenses and our capacity as a true one-stop-shop for repairs, surveys, and supplies make us the efficient, cost-conscious solution your bottom line demands.

Take the next step towards a more profitable and efficient operation. Contact our experts to develop a cost-reduction strategy for your fleet at the Panama Canal. Put your transit in our hands and see the difference an expert partner can make.

Frequently Asked Questions

What is the single biggest operating cost for a commercial ship?

Bunker fuel is overwhelmingly the largest single operating expense for any commercial vessel, often representing 50-60% of total voyage costs. This expenditure is directly impacted by volatile market prices, engine efficiency, voyage speed, and overall vessel condition. Consequently, managing fuel consumption through optimized routing, performance monitoring, and proactive maintenance is the most critical factor for ship owners and operators aiming to control their operational budget and maintain profitability in a competitive global market.

How much can regular propeller polishing really save on fuel costs?

A consistent propeller polishing schedule delivers significant and measurable savings, typically reducing fuel consumption by 3-8%. A smooth, clean propeller minimizes hydrodynamic drag, allowing it to generate maximum thrust with less engine power. This enhanced propulsion efficiency is a direct, cost-effective tactic for operators seeking solutions for how to reduce ship operating costs. Neglecting this maintenance allows marine growth to create roughness that directly increases fuel burn and erodes voyage profitability.

What’s the difference between OpEx (Operating Expenses) and CapEx (Capital Expenses) in shipping?

OpEx, or Operating Expenses, are the recurring, day-to-day costs required to run a vessel. This category includes crew wages, provisions, insurance, lubricants, routine maintenance, and bunker fuel. In contrast, CapEx, or Capital Expenses, are major, long-term investments that improve a vessel’s value or extend its operational life. Examples include purchasing a new ship, installing a ballast water treatment system, or conducting a major engine overhaul. Efficient management of both is essential for fleet profitability.

Why is a Planned Maintenance System (PMS) so important for modern vessels?

A Planned Maintenance System (PMS) is a fundamental tool for ensuring vessel reliability, safety, and cost control. It transforms maintenance from a reactive to a proactive model by scheduling all necessary tasks, managing spare parts inventory, and documenting equipment history for compliance. This systematic approach prevents unexpected equipment failures, which lead to expensive emergency repairs and commercially damaging downtime. A robust PMS is therefore an essential component of an effective operational strategy.

How does biofouling on a ship’s hull increase operating costs?

Biofouling-the accumulation of marine organisms like slime, algae, and barnacles-creates significant hydrodynamic drag on a ship’s hull. This increased resistance forces the main engine to work harder and consume substantially more fuel to maintain its required speed. Even a thin layer of slime can increase fuel consumption by over 10%, while heavier growth has a much greater impact. This direct link to fuel efficiency makes proactive hull maintenance a top priority for cost-conscious operators.

Can I perform underwater hull cleaning instead of dry-docking?

Yes, underwater hull cleaning is a standard and highly effective procedure performed between scheduled dry-dockings. It is a cost-efficient solution to remove biofouling, restore hull smoothness, and improve fuel efficiency without taking the vessel out of service. However, it is a maintenance tool, not a substitute for dry-docking. A full dry-dock is still required for comprehensive inspections, major repairs, antifouling paint application, and servicing equipment that cannot be accessed while afloat.