A booked transit slot at the Panama Canal is a critical asset. Losing it due to a minor, preventable failure is not just an operational headache-it’s a significant financial blow, often accompanied by a massive ‘Disruption Charge’ from the Panama Canal Authority (PCA). With current drought restrictions adding another layer of complexity, the stakes for a flawless passage have never been higher. For ship owners and charterers, successfully avoiding vessel downtime panama canal transit requires more than just good seamanship; it demands meticulous preparation and expert local knowledge.

This mariner’s checklist is your essential guide to a smooth, on-schedule passage. We provide the actionable intelligence you need to master pre-transit checks, navigate complex PCA regulations, and identify the most common-and costly-pitfalls. Put these expert solutions to work to ensure your vessel is prepared, compliant, and supported by a reliable local partner for a penalty-free transit. Your goal is a seamless passage, and our expertise is how you achieve it.

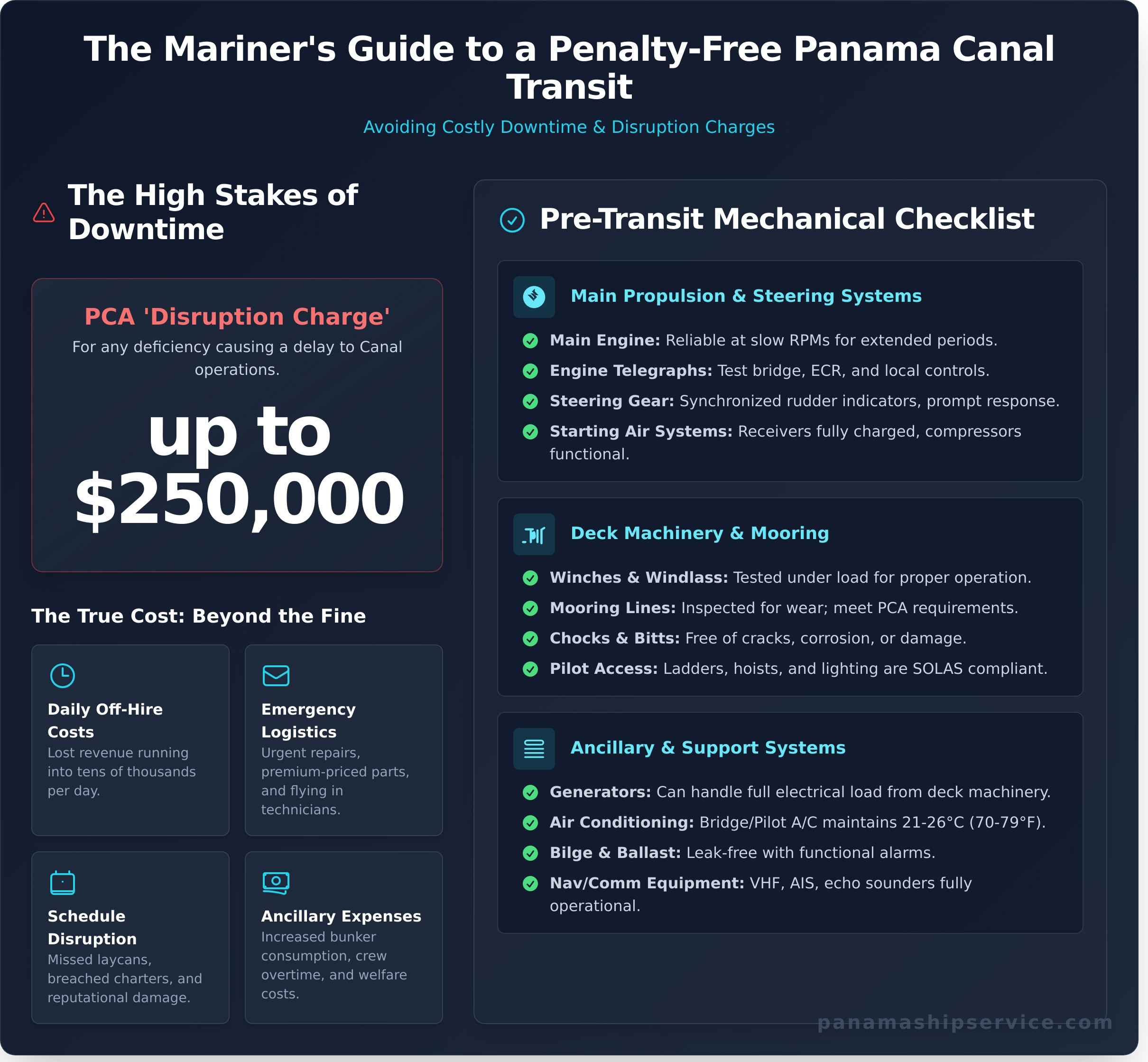

The High Stakes of Downtime at the Panama Canal

In global shipping, timing is everything. Nowhere is this more apparent than at the Panama Canal, a critical chokepoint where any delay has immediate and costly consequences. Unlike open water, the Canal operates on a system of fixed transit slots, a highly orchestrated schedule that leaves no room for error. A single vessel experiencing a mechanical failure or non-compliance issue can trigger a domino effect, disrupting the passage of dozens of other ships. Understanding the immense operational and financial pressures is the first step in successfully avoiding vessel downtime Panama Canal transits. The global significance of the Panama Canal as a facilitator of world trade is precisely why the Panama Canal Authority (PCA) enforces some of the strictest operational standards in the maritime industry.

The canal itself, a marvel of concrete engineering, is a powerful reminder that all great operations depend on a solid foundation. While on a different scale, for an example of expertise in modern concrete and hardscaping services, you can visit Peninsula Concrete Contractors.

Understanding the PCA ‘Disruption Charge’

The Panama Canal Authority (PCA) enforces its stringent requirements with significant financial penalties, most notably the ‘Disruption Charge’. This is not a minor fee; it is a substantial fine levied against any vessel whose deficiency, no matter how small, causes a delay to Canal operations. Fines can reach up to $250,000 USD for serious incidents. The charge underscores the PCA’s zero-tolerance policy for unpreparedness. It serves as a powerful incentive for owners and operators to ensure their vessels are in perfect compliance before arrival.

Calculating the True Cost: Beyond the Fine

The Disruption Charge is only the beginning of the financial fallout. The true cost of an unplanned delay multiplies quickly when you factor in the cascading operational expenses. A comprehensive strategy for avoiding vessel downtime at the Panama Canal must account for these hidden costs, which often dwarf the initial fine:

- Daily Off-Hire Costs: Every hour a vessel is delayed is an hour of lost revenue, with off-hire costs easily running into tens of thousands of dollars per day.

- Emergency Logistics: The expense of urgent repairs, sourcing spare parts at a premium, and flying in specialized technicians to a remote location adds up rapidly.

- Schedule Disruption: A delay at the Canal can jeopardize future voyage schedules, leading to missed laycans, breached charter party agreements, and significant reputational damage with clients.

- Ancillary Expenses: Additional costs include increased bunker consumption while idle or maneuvering, as well as potential crew overtime and associated welfare expenses.

Pre-Transit Mechanical Checklist: Top Failure Points to Address

Proactive maintenance is not just best practice; it is the fundamental strategy for avoiding vessel downtime Panama Canal transits. A significant percentage of delays and costly penalties stem from mechanical failures that could have been identified and rectified pre-arrival. This checklist is not exhaustive but focuses on the most common deficiencies cited by the Panama Canal Authority (PCA). Addressing these critical points is a non-negotiable step to ensure an efficient, predictable, and successful passage.

Main Propulsion and Steering Systems

The ability to maneuver with precision is paramount within the Canal’s narrow confines. Your vessel’s core systems must be flawless. Any failure here will result in an immediate stoppage of the transit operation, leading to significant delays. Our experts recommend a thorough pre-arrival inspection covering:

- Main Engine Readiness: Confirm the engine can operate reliably at slow ahead RPMs for extended periods without issue.

- Engine Telegraphs: Test bridge, engine room, and local control station telegraphs for full and accurate functionality.

- Steering Gear: Verify that rudder angle indicators are synchronized and that the steering gear responds promptly and correctly from all control positions.

- Starting Air Systems: Ensure main starting air receivers are fully charged to optimal pressure and that compressors are in good working order.

Deck Machinery and Mooring Equipment

Mooring operations are constant and demanding during transit. Equipment failure not only endangers the crew and pilots but can also damage canal infrastructure. Ensure all machinery is fully operational and compliant. All equipment must meet the strict standards outlined in the official Panama Canal Authority regulations to prevent any compliance-related delays.

- Winches and Windlass: Test all mooring winches and the anchor windlass under load to confirm proper operation.

- Mooring Lines: Inspect all lines for signs of wear, fraying, or degradation. Ensure they meet PCA size, length, and strength requirements.

- Chocks and Bitts: Check for any cracks, corrosion, or damage that could compromise their integrity under high tension.

- Pilot Access: Verify that pilot ladders, hoists, and associated lighting are in perfect condition and fully compliant with SOLAS regulations.

Ancillary and Support Systems

While not directly involved in propulsion, support systems are critical for operational continuity and compliance. A failure in these areas, such as the pilot’s air conditioning, can be grounds for the PCA to halt your transit. A comprehensive check ensures the vessel’s environment and support functions meet all requirements for a smooth operation.

- Generators: Confirm that generators can handle the full electrical load required for simultaneous use of deck machinery and other equipment.

- Air Conditioning: Test the A/C in the bridge and pilot cabin to ensure it maintains the mandatory temperature range of 21-26°C (70-79°F).

- Bilge and Ballast Systems: Inspect for any leaks or operational faults. Ensure bilge alarms are functional.

- Navigation & Communication: Test all required equipment, including VHF radios, AIS, and echo sounders, to ensure they are fully operational.

Navigating PCA Compliance: Beyond Mechanical Fitness

A vessel in perfect mechanical condition can still face significant, costly delays at the Panama Canal. Operational and administrative readiness are equally critical components for a smooth transit. Overlooking these details not only risks fines and schedule disruptions but also signals a lack of preparation to the Panama Canal Authority (PCA) pilots who board your vessel. Demonstrating comprehensive compliance is a key part of avoiding vessel downtime panama canal and showcases the professionalism of your operation.

Success requires a proactive approach to non-mechanical requirements, from precise draft management to flawless documentation. These factors are not formalities; they are core operational mandates enforced by the PCA.

Vessel Draft and Trim Management

The Canal’s operational capacity is directly tied to water levels in Gatun Lake, leading to dynamic and strictly enforced vessel draft restrictions. Arriving with a draft that exceeds the current maximum permissible limit will result in an immediate denial of transit until the vessel complies. Accurate draft calculations must be performed and verified long before arrival. To eliminate any margin of error, we strongly recommend a professional draft survey to ensure your declared figures are precise and defensible.

Documentation and Crew Readiness

Administrative precision is as critical as navigational skill. The PCA leaves no room for error, meticulously outlining every prerequisite in documents like the official ACP ‘N-01 Vessel Requirements’. Before arrival, your vessel must confirm:

- Valid Certification: All required vessel, officer, and crew certificates must be current, valid, and readily accessible for inspection. Expired or missing documents are a common cause of delay.

- Crew Preparedness: The bridge team must be well-rested and fully briefed on Canal transit procedures, including mooring arrangements, pilot communication protocols, and emergency responses.

- Sanitation and MARPOL Compliance: All sanitation declarations, MARPOL-related logbooks, and ballast water management plans must be meticulously completed and accurate.

Managing this extensive documentation is a critical task where mistakes are costly. Our agency services ensure your paperwork is flawless, preventing compliance-related delays and safeguarding your schedule.

Proactive Strategy: Securing a Reliable Partner in Panama

While understanding regulations and preparing your vessel are critical, the most effective strategy is proactive: aligning with a local expert before you need one. A trusted partner in Panama acts as a direct extension of your operations team, on the ground and ready to execute. This integration streamlines communication, accelerates service delivery, and generates significant cost savings by preventing costly delays. Instead of reacting to problems, you have a solution already in place.

The ‘One-Stop-Shop’ Advantage for Efficiency

Consolidating your vessel’s needs-from urgent repairs and class surveys to husbandry and supplies-with a single, qualified provider is a powerful efficiency multiplier. It eliminates the complexity and potential for miscommunication inherent in coordinating multiple vendors. With an integrated partner, you benefit from unified planning, seamless execution, and the assurance that every service is performed to a consistent, high standard, saving you time and administrative overhead.

24/7 Emergency Response Capability

Operational challenges at the Canal adhere to no schedule. A critical failure can occur at any hour, and every minute of delay translates to direct financial loss. A dedicated local partner with 24/7 emergency response capability is non-negotiable. They provide immediate action, leveraging an established network of on-call technicians and suppliers to deploy solutions rapidly. This round-the-clock support is fundamental to avoiding vessel downtime Panama Canal and offers invaluable peace of mind.

What to Look For in a Panama Ship Service Provider

Vetting a potential partner is a critical step. Your success depends on their expertise and reliability. Prioritize providers who demonstrate:

- Extensive Local Experience: A deep, practical understanding of Panama Canal Authority (PCA) regulations and undocumented operational nuances is essential for smooth service delivery.

- Certified Technicians: Verify they employ a team of certified and class-approved technicians for all major repair and maintenance disciplines.

- Comprehensive In-House Services: A true one-stop-shop has the internal resources to handle a wide range of needs without relying heavily on third-party contractors.

- Proven Track Record: Ask for client testimonials and case studies that prove their performance and reliability under pressure.

The most effective strategy for a successful transit is to have an expert on your side before a problem arises. Panama Ship Service is your trusted partner for efficient, reliable, and cost-conscious solutions at the Canal.

Your Trusted Partner for a Flawless Canal Transit

A successful Panama Canal transit is a direct result of meticulous preparation. As this checklist highlights, success hinges on two core principles: proactive maintenance to address common mechanical failure points and a thorough understanding of evolving PCA compliance regulations. Overlooking either can lead to significant financial and operational setbacks. The most effective strategy for avoiding vessel downtime panama canal is to move beyond simple checklists and secure an expert partner on the ground.

Panama Ship Service is that trusted partner. With decades of experience, we provide the solutions you need to navigate PCA requirements with confidence. As a comprehensive one-stop-shop for all vessel needs, we offer everything from pre-transit technical support to 24/7 emergency repair services, ensuring your passage is timely and cost-effective. We are the experts, so you don’t have to be.

Protect your schedule and your bottom line. Contact us for a pre-transit consultation and avoid costly delays. Put your transit in our hands and sail through with confidence.

Frequently Asked Questions

What is the most common reason for a vessel receiving a ‘Disruption Charge’ at the Panama Canal?

The most common reasons for a Disruption Charge stem from non-compliance with Panama Canal Authority (ACP) regulations discovered during pre-transit inspections. These often involve deficiencies in critical equipment such as main engine issues, steering gear failures, or non-compliant pilot boarding arrangements (e.g., ladders). These findings can delay the vessel’s transit, leading to significant financial penalties. Proactive maintenance and pre-arrival checks are essential to prevent these costly charges and ensure a smooth passage.

How can I verify the current maximum draft allowed for Panama Canal transit?

The Panama Canal Authority (ACP) officially announces the maximum allowable draft through “Advisories to Shipping.” These are published on the official ACP website and are the definitive source. As water levels in Gatun Lake can fluctuate, these advisories are updated regularly. For the most current and reliable information, we recommend consulting the ACP website directly or contacting your trusted local agent who monitors these updates constantly to ensure your vessel remains in full compliance.

Can critical repairs be performed at anchorage in Panama if an issue is found?

Yes, a wide range of critical repairs can be completed efficiently while a vessel is at the Panama Canal anchorage. Services such as underwater hull cleaning, propeller polishing, steel work, and engine component repairs are routinely performed by qualified teams. Engaging an experienced and responsive service provider is crucial to mobilize certified technicians and equipment rapidly, ensuring repairs are completed to class standards without jeopardizing the vessel’s scheduled transit slot and operational timeline.

How far in advance should we schedule services like underwater cleaning or repairs before transit?

To ensure seamless coordination, we recommend scheduling all services at least 72 to 96 hours prior to your vessel’s arrival. This lead time is essential for securing necessary permits from the Panama Maritime Authority, mobilizing qualified personnel, and preparing all required equipment. Proper advance planning is a critical component for avoiding vessel downtime panama canal, as it guarantees that all work is completed efficiently without impacting your assigned transit schedule.

What happens if my vessel misses its scheduled transit slot due to a delay?

Missing a scheduled transit slot results in significant consequences. The booking fee is typically forfeited, and the vessel loses its place in the queue, being rescheduled among the un-booked vessels waiting for transit. This can cause delays of several days, leading to substantial increases in operational costs, fuel consumption, and charter party disputes. Proactive management and having a reliable partner on the ground is the best defense against such costly disruptions.

Is it better to use a single company for all ship services in Panama?

Absolutely. Consolidating all services-from vessel agency and repairs to surveys and MARPOL disposal-with a single, expert provider is the most effective strategy. This one-stop-shop approach streamlines communication, eliminates coordination errors between multiple vendors, and provides a single point of accountability. It ensures all activities are synchronized with the vessel’s schedule, making it the most efficient and cost-conscious method for avoiding vessel downtime panama canal and guaranteeing a successful transit.