Every hour a damaged vessel remains idle at the Panama Canal, operational costs mount and schedules unravel. The search for a fast, permanent repair is often complicated by unqualified teams and the risk of temporary fixes that fail to meet class standards. In this high-stakes environment, finding a trusted partner for certified underwater welding Panama is critical to protecting your asset and your timeline. You need a solution that is not only immediate but also permanent and fully compliant.

This guide details how our rapidly-deployed, class-approved diver-welder teams deliver that solution. Available 24/7, we execute permanent underwater welding repairs designed to minimize vessel off-hire time and eliminate canal transit delays. We will walk you through our process for ensuring the highest safety standards, providing clear communication and documentation, and getting your vessel safely back on its voyage. Put your repair in our hands and let our experts handle the rest.

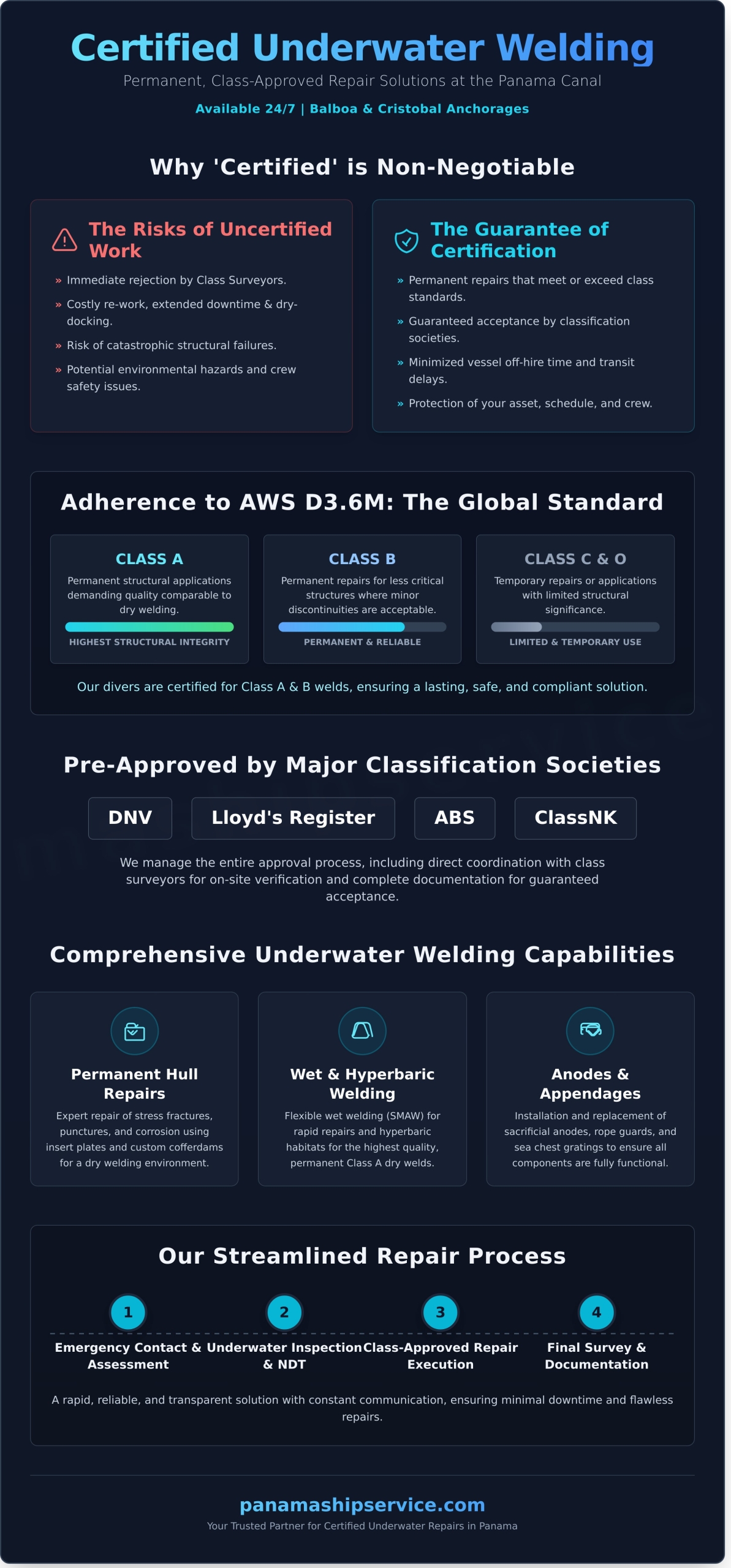

Why ‘Certified’ is Non-Negotiable for Underwater Welding in Maritime

In the high-stakes maritime industry, underwater welding is far more than a simple repair task-it is a critical operation where precision and safety are paramount. This highly specialized field involves complex underwater welding techniques that demand rigorous training and adherence to strict international standards to ensure the safety and integrity of the vessel. Opting for uncertified welders exposes ship owners and operators to severe risks, including catastrophic structural failures, environmental hazards, and potential harm to the crew.

More importantly, uncertified work is a direct route to costly operational delays. When a vessel undergoes inspection, repairs performed by unqualified personnel are immediately rejected by classification society surveyors. This rejection necessitates a complete re-work by a certified team, leading to extended downtime, unplanned dry-docking expenses, and significant disruption to sailing schedules. In short, a decision meant to save costs initially results in far greater financial and logistical penalties.

Understanding AWS D3.6M Certification

The American Welding Society’s AWS D3.6M specification is the globally recognized standard for underwater welding, providing a clear benchmark for quality and safety. It classifies welds based on their intended application and structural importance:

- Class A: Intended for permanent structural applications, these welds must meet quality standards comparable to those performed in a dry environment.

- Class B: Suitable for less critical permanent repairs where some weld discontinuities are tolerable.

- Class C & O: Reserved for temporary repairs or applications with limited structural significance.

Our expert welder-divers are certified to perform Class A and Class B welds, ensuring that every repair we undertake meets the highest requirements for permanent structural integrity. When you require certified underwater welding panama, our adherence to AWS D3.6M is your guarantee of a lasting, safe, and compliant solution.

Approval by Major Classification Societies

A welder’s certification is only part of the equation. For a permanent in-water repair to be accepted, the procedure itself must be approved by the vessel’s classification society. Our welding procedures are pre-approved by major societies, including DNV, Lloyd’s Register (LR), the American Bureau of Shipping (ABS), and ClassNK.

We manage the entire approval process to ensure a seamless experience for our clients. This includes direct coordination with the attending class surveyor for on-site verification and the meticulous preparation of all required documentation. By entrusting your repairs to us, you are assured of a solution that is not only technically sound but also fully compliant and guaranteed to pass inspection, keeping your vessel on schedule and operational.

Our Underwater Welding Capabilities at the Panama Canal

Time-critical vessel repairs at the Panama Canal demand expert execution and rapid deployment. We provide comprehensive solutions, and our teams are on call for certified underwater welding panama 24/7 at both the Balboa and Cristobal anchorages, ensuring your operational schedule is maintained. Our qualified teams are proficient in working with all marine-grade steels and thicknesses, utilizing state-of-the-art equipment for both welding and non-destructive testing (NDT) to verify the integrity of every repair.

Permanent Hull Damage Repairs

Our welder-divers are experts in addressing all forms of hull damage. We execute permanent, class-approved repairs for stress fractures, punctures, and severe corrosion. For localized repairs, we fabricate and install custom cofferdams to create a dry welding environment. In cases of extensive damage, we perform precise cropping and fitting of insert plates, fully restoring the hull’s structural integrity. This expertise extends to appendages, including rudders, bilge keels, and propeller nozzles.

Wet Welding vs. Hyperbaric (Dry) Welding

As a leading provider of certified underwater welding panama, we offer both wet and hyperbaric solutions tailored to your vessel’s needs. While wet welding (SMAW) provides a rapid and flexible option for certain repairs, we deploy hyperbaric welding habitats for permanent, class-approved repairs demanding the highest quality. These create a dry, controlled environment for superior weld penetration. Our certified divers execute both methods, adhering strictly to international safety standards for commercial diving and ensuring the most effective solution is chosen.

Anode and Appendage Installation/Repair

Protecting your vessel from galvanic corrosion is critical for its longevity. Our teams specialize in the installation and replacement of sacrificial anode systems. We expertly weld new anode brackets and install anodes according to your vessel’s protection plan. Additionally, we handle the underwater repair or replacement of other critical appendages, such as damaged rope guards and sea chest gratings, ensuring all underwater components are secure and fully functional before you transit.

The Repair Process: From Inspection to Class-Approved Completion

At Panama Ship Service, we understand that unexpected hull damage requires a rapid, reliable, and transparent solution. Our process for certified underwater welding in Panama is built on a systematic approach that prioritizes quality, safety, and constant communication with your vessel’s superintendent and captain. From the initial call to the final class-approved report, our goal is to execute flawless repairs while minimizing vessel downtime and operational disruption.

Step 1: Emergency Contact and Initial Assessment

Your first contact initiates our rapid response protocol. We require essential preliminary information-such as the vessel’s location, damage reports, and any available photos-to understand the scope of the issue. Based on this, our technical team provides a preliminary repair plan and a competitive quotation, ensuring you have a clear understanding of the proposed solution and costs. Our inspection team is then immediately mobilized to the vessel’s location.

Step 2: Underwater Inspection and NDT

Upon arrival, our certified diver-technicians conduct a thorough underwater inspection using high-resolution CCTV cameras to provide a live feed to the surface team and vessel representatives. To accurately assess the extent of the damage and ensure structural integrity, we employ Non-Destructive Testing (NDT) methods like Magnetic Particle Inspection (MPI) or Ultrasonic Testing (UT). These findings are compiled into a detailed damage report for you and the relevant Classification Society, allowing us to finalize the precise repair strategy and timeline.

Step 3: Welding Execution and Quality Control

With an approved plan, our team establishes a safe and efficient on-site work area. Every stage of the welding is monitored in real-time by a surface supervisor who maintains constant communication with the welder-diver. Our procedures adhere strictly to the globally recognized AWS D3.6M Specification for underwater welding, guaranteeing the highest standards of quality. We perform continuous quality checks throughout the process and coordinate directly with the class surveyor for on-site verification when required.

Step 4: Final Inspection and Reporting

Once welding is complete, the repaired area is meticulously cleaned and prepared for a final inspection. We conduct post-weld NDT to confirm the integrity and quality of the permanent repair, ensuring it meets all class requirements. You receive a comprehensive final report package containing all certifications, high-definition video footage, detailed photographs, and NDT results. This complete documentation provides a permanent record and satisfies all regulatory and insurance obligations. Contact our team for a rapid assessment of your repair needs.

Rapid Response and Mobilization for Vessels in Panama

At the Panama Canal, timing is everything. Unscheduled delays for hull damage or necessary repairs can disrupt transit schedules, leading to significant financial losses. Panama Ship Service understands this urgency. We have built our operations around providing an immediate, expert response to minimize your vessel’s downtime and protect your bottom line. Our mission is to deliver fast, reliable, and fully compliant underwater services precisely when and where you need them.

Our readiness is absolute, operating 24 hours a day, 365 days a year. An emergency call activates our highly-trained technical teams and mobilizes our fleet of fully-equipped, high-speed dive support vessels. Each craft is a self-contained workshop, stocked with state-of-the-art welding equipment, cutting tools, and inspection technology. This ensures that when we arrive on-site, our certified divers have everything required to execute a permanent repair without delay. We eliminate the lag time associated with sourcing equipment, allowing us to begin work immediately.

Navigating the administrative requirements for port operations can be a complex and time-consuming challenge. Our team possesses deep expertise in coordinating with the Panama Canal Authority (ACP) and local port authorities. We manage the entire permit acquisition process efficiently, leveraging our established relationships to secure the necessary clearances swiftly, ensuring our teams can access your vessel without bureaucratic delays.

24/7 Emergency Hotline and Coordination

For immediate assistance, contact our emergency hotline. Our technical team is on permanent standby to assess your needs and deploy a qualified team. We act as your single point of contact, coordinating directly with your vessel’s agents and port authorities to ensure a seamless and efficient service delivery from the moment you call.

Serving All Panama Canal Anchorages and Terminals

Our logistical advantage allows us to provide rapid certified underwater welding in Panama across all key locations. We maintain a constant presence at both entrances to the Canal, ensuring swift deployment to:

- Pacific Side: Balboa Port and Anchorage

- Atlantic Side: Cristobal Port and Anchorage

- All nearby terminals and designated waiting areas

This strategic positioning is crucial for vessels awaiting transit, allowing us to perform critical repairs without impacting your scheduled slot. Request an urgent quote for underwater welding in Panama.

Your Trusted Partner for Certified Underwater Repairs in Panama

When navigating the critical passage of the Panama Canal, compromising on vessel integrity is not an option. As we’ve detailed, the foundation of a successful underwater repair rests on two pillars: verifiable certification and rapid, expert execution. Our process guarantees both. Our team of AWS D3.6M certified welder-divers delivers solutions that are not only fast but are also approved by all major IACS Classification Societies, ensuring full compliance and seaworthiness. For dependable, class-approved certified underwater welding panama, our expertise is your greatest asset in minimizing downtime and protecting your schedule.

Unexpected damage demands an immediate and decisive response. Our teams are strategically positioned for 24/7 rapid mobilization throughout Panama, ready to address your needs at a moment’s notice. Don’t let underwater issues disrupt your transit, compromise your vessel’s safety, or inflate your operational budget. Contact Our 24/7 Underwater Repair Team for an Immediate Quote and let us provide the efficient, reliable solution your operations require. Put your vessel in our expert hands.

Frequently Asked Questions

What certifications do your underwater welder-divers hold?

Our welder-divers are certified to the highest international standards, including AWS D3.6M for Underwater Welding. They also hold approvals from major IACS classification societies such as Lloyd’s Register (LR), the American Bureau of Shipping (ABS), and DNV. This ensures every repair meets rigorous quality and safety requirements. We invest in continuous training to maintain our position as a leading provider for certified underwater welding in Panama, guaranteeing compliance and excellence for your vessel.

Can you perform permanent underwater repairs that are approved by class societies?

Yes, we specialize in permanent underwater repairs that are fully approved by all major classification societies. Our procedures are designed to meet and exceed class standards for permanent, in-water hull repairs, crack arrests, and insert plate installations. We coordinate directly with the attending class surveyor throughout the project, from initial inspection to final approval, ensuring the repair is documented and certified to maintain your vessel’s classification without disrupting its schedule.

What is your typical response time for an emergency call-out in Panama?

We operate 24/7/365 to address emergency repairs with maximum urgency. For vessels at the Pacific or Atlantic anchorages of the Panama Canal, our rapid-response teams can typically be mobilized and on-site within 2-4 hours of confirmation. This swift deployment minimizes vessel downtime and associated costs. Our strategic location and streamlined logistics are engineered to provide the fastest and most reliable emergency underwater welding services in the region.

What information do you need from us to provide an accurate quote?

To provide a fast and accurate quote, please supply the vessel’s name/IMO number, its exact location (e.g., Balboa or Cristobal anchorage), and a detailed description of the required repair. Any available drawings, photographs, or inspection reports of the damaged area are extremely helpful. Also, please specify the vessel’s classification society. This information allows our technical team to assess the scope of work and promptly deliver a comprehensive, competitive proposal.

How do you ensure the safety of the welding operations?

Safety is our highest priority. Every operation begins with a comprehensive Job Safety Analysis (JSA) and a pre-dive briefing. We strictly adhere to IMCA guidelines, utilizing surface-supplied diving equipment and constant two-way communication between the diver and the surface supervisor. All equipment is regularly inspected and certified. Our commitment to rigorous safety protocols ensures the well-being of our team and the integrity of your asset throughout the entire welding process.

What kind of final documentation and report will we receive?

Upon completion, you will receive a comprehensive service report. This package includes a detailed written summary of the work performed, pre- and post-repair high-definition photographs, and continuous underwater video footage of the entire operation. For class-approved repairs, all necessary certification and endorsement from the attending surveyor is included. This thorough documentation provides a complete record for your vessel’s logs and verifies the quality of our services.