For ship owners and operators, the mandatory dry-docking schedule represents one of the largest operational and financial hurdles. The associated costs, logistical complexities, and significant vessel downtime can disrupt schedules and erode profitability. But there is a proven, cost-conscious solution to maintain compliance without taking your vessel out of service. A strategically executed in-water survey class approved by societies like ABS, DNV, and Lloyd’s Register offers a powerful alternative, allowing you to meet regulatory requirements while the vessel remains operational and generating revenue.

This guide provides the essential information you need to leverage this efficient process. We will detail the specific requirements, the advanced underwater technology used, and the significant time and cost savings you can achieve. You will understand how to partner with a certified provider at a key transit point like the Panama Canal to receive a detailed, professional report that guarantees class approval, keeping your vessel on schedule and protecting your bottom line. We are the experts, so you don’t have to be.

What is a Class-Approved In-Water Survey (IWS)?

In the high-stakes maritime industry, time is money. An In-Water Survey (IWS) is an expert method for inspecting a vessel’s hull and underwater components while it remains afloat, providing a cost-conscious and efficient alternative to traditional dry-docking. To understand the fundamentals of What is an In-Water Survey?, it is best viewed as a strategic solution that minimizes operational downtime and associated expenses. Instead of removing the vessel from service, a team of qualified divers uses advanced technology to perform a comprehensive examination right at the port or anchorage.

Crucially, for the inspection to satisfy regulatory requirements, it must be an in-water survey class approved by the vessel’s Classification Society. These societies, such as members of the International Association of Classification Societies (IACS), set the stringent standards that both the survey procedure and the service provider must meet. The ultimate goal is to verify the vessel’s structural and operational integrity below the waterline. This service is also widely known in the industry as an Underwater Inspection in Lieu of Dry-docking (UWILD).

Purpose and Scope of In-Water Surveys

A class-approved IWS is not a superficial check. It is a detailed examination designed to fulfill specific regulatory obligations and provide a clear picture of the vessel’s condition. The scope is comprehensive and typically includes:

- Fulfilling requirements for intermediate or special surveys mandated by the Classification Society.

- Close visual inspection of the underwater hull, propellers, rudder, sea chests, and other critical appendages.

- Assessing the condition of the hull coating, checking for marine fouling, and identifying any potential damage like cracks or indentations.

- Verifying the overall structural integrity of the vessel below the waterline to ensure it remains seaworthy.

When Can an IWS Replace a Dry-Dock Survey?

While highly advantageous, an in-water survey class approved is subject to specific criteria set by the governing Class Society. Eligibility depends on several factors, and approval is granted on a case-by-case basis. Common conditions include:

- Survey Type: IWS is most frequently used to satisfy intermediate survey requirements, which occur between the five-year special surveys.

- Vessel Age: Vessels under 15 years of age are often considered prime candidates, as their condition is generally more predictable.

- Consecutive Surveys: Many class societies permit up to two consecutive IWS in a five-year cycle, deferring the need for dry-docking.

- Class Rules: The final decision always rests with the vessel’s specific Classification Society rules and is also dependent on vessel type and operational history.

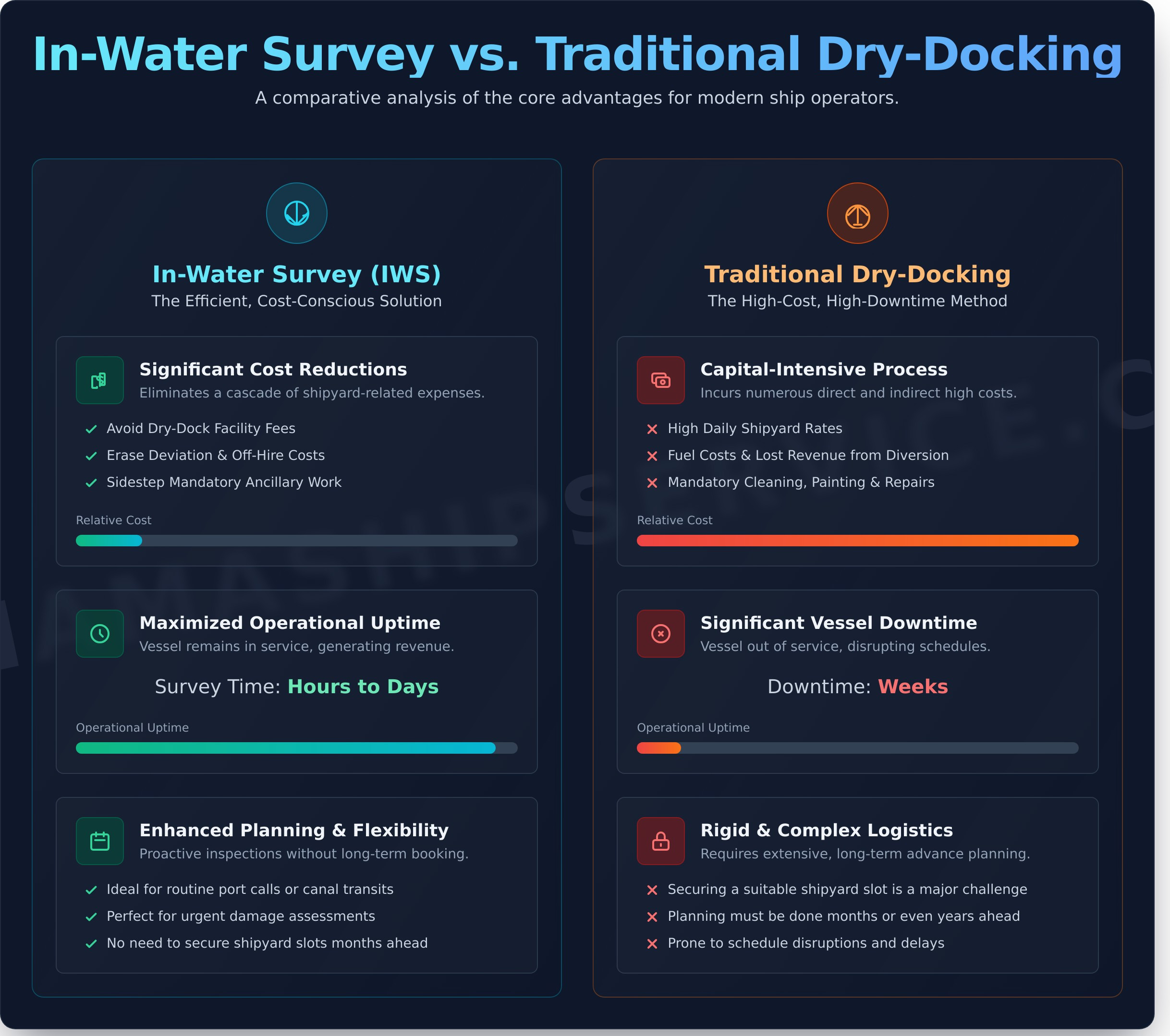

The Core Advantages: Why Choose IWS Over Dry-Docking?

For ship owners and charterers, time is money. The primary driver for choosing an In-Water Survey (IWS) over traditional dry-docking is an unwavering focus on efficiency. An IWS minimizes disruption to a vessel’s trading schedule, a critical advantage in the fast-paced shipping industry. This solution aligns perfectly with the time-sensitive nature of canal transits, where every hour saved directly impacts profitability. The financial and operational benefits are not just marginal-they are significant and immediate.

Significant Cost Reductions

The most compelling argument for an in-water survey class approved by your society is the dramatic reduction in expenses. Dry-docking is a capital-intensive process that goes far beyond the survey itself. By keeping your vessel in the water, you eliminate a cascade of associated costs.

- Dry-Dock Facility Fees: Avoid the high daily rates and associated service charges of shipyards.

- Deviation and Off-Hire Costs: Erase the significant expenses of diverting from your trade route, including fuel, pilotage, and lost revenue.

- Ancillary Work: Sidestep mandatory cleaning, hull painting, and other tasks often required during a dry-dock stay.

Ultimately, the total cost of an IWS can be a small fraction of what a full dry-docking would entail, delivering a direct boost to your bottom line.

Maximized Operational Uptime

Operational continuity is paramount. An IWS ensures your vessel remains in service, continuing to generate revenue while meeting its classification requirements. Instead of weeks of downtime in a shipyard, a comprehensive survey can often be completed in a matter of hours or a few days. This efficient process is ideally suited for completion during routine operations, such as while loading or discharging cargo at port or while waiting at anchor. By avoiding costly delays and schedule disruptions, you maintain your competitive edge and honor your charter party agreements without interruption.

Enhanced Planning and Flexibility

Securing a slot at a suitable dry-dock facility can be a logistical challenge, often requiring months of advance planning. In contrast, an IWS offers far greater scheduling flexibility. This allows for proactive hull inspections between scheduled dry-dockings, identifying potential issues before they become critical. This adaptability is crucial, as the survey must still meet strict international standards. For example, maritime bodies outline the specific Key Requirements for a Class-Approved Survey to ensure its validity. This method is also highly effective for pre-purchase inspections or urgent damage assessments, providing vital information without the commitment of dry-docking. Calculate your potential savings with our experts.

The IWS Process: From Initial Request to Final Approval

A successful in-water survey is far more than a simple dive; it is a meticulously managed project requiring precise coordination. The process demands seamless collaboration between the ship owner, the attending Classification Society surveyor, and the expert dive team. Missteps at any stage can lead to delays, added costs, or even a rejected report. Panama Ship Service removes this risk by managing the entire process for you. We are experts in navigating these complexities, ensuring a smooth, efficient operation and delivering a guaranteed-approved report that satisfies all class requirements.

Step 1: Pre-Survey Planning and Documentation

The foundation of a successful survey is laid long before our divers enter the water. This critical preparatory phase involves a detailed review of the vessel’s survey status and specific class rules. We align our procedures with the stringent standards outlined in official guidelines like the ClassNK In-Water Survey Requirements to ensure full compliance. Our team handles every detail:

- Developing a comprehensive dive plan and job-specific safety protocol.

- Coordinating schedules and technical requirements directly with the attending class surveyor.

- Submitting all necessary documentation for preliminary review and approval.

Step 2: The On-Site Underwater Inspection

With a class-approved plan in place, our certified inspection divers execute the on-site survey. The operation is designed for maximum transparency and accuracy. A live, high-resolution video feed is transmitted from the diver’s camera to a topside monitoring station, allowing the class surveyor to witness the entire inspection in real-time and direct the diver as needed. This systematic in-water survey class approved procedure ensures complete coverage of the hull, rudder, propeller, sea chests, and all other critical appendages, all facilitated by clear, uninterrupted two-way communication between the diver, dive supervisor, and surveyor.

Step 3: Reporting and Class Endorsement

The final stage transforms field data into an official, endorsed document. Our team meticulously compiles all video footage, high-resolution still images, and diver observations into a comprehensive report. This document provides a clear and detailed account of the vessel’s underwater condition, highlighting any findings with precision. The final report is submitted directly to the Classification Society surveyor for their review and official endorsement. Securing this final signature completes the survey requirement, allowing your vessel to continue its voyage without the costly disruption of dry-docking.

Key Requirements for a Class-Approved Survey

Classification societies like ABS, DNV, and Lloyd’s Register enforce stringent standards for In-Water Surveys (IWS). These are not guidelines; they are mandatory prerequisites designed to ensure the inspection’s quality and integrity rival that of a traditional dry-dock examination. Meeting these requirements is non-negotiable for approval. A failure to comply with any single standard can lead to a rejected survey, resulting in costly delays and operational disruption.

At Panama Ship Service, we utilize state-of-the-art technology and certified personnel to ensure every condition is met, providing a seamless and efficient path to certification. A successful in-water survey class approved outcome depends on three critical areas.

Certified Diving Team and Equipment

The quality of the inspection rests on the expertise of the team and the capability of their tools. Classification societies require:

- Certified Personnel: Divers must hold current certifications from major IACS members, verifying their competence in underwater inspection techniques.

- Advanced Visual Systems: Professional-grade, surface-controlled underwater CCTV and high-intensity lighting systems are essential for capturing clear, detailed footage for the attending surveyor.

- Mandatory Safety Systems: Surface-supplied air and hard-wired, two-way communication systems are required to ensure diver safety and maintain constant contact between the diver, supervisor, and surveyor.

- Precision Instruments: Where required, calibrated Ultrasonic Thickness Measurement (UTM) gauges are used to verify hull plating thickness against approved specifications.

Suitable Environmental Conditions

Even the most qualified team is limited by the operational environment. The survey location must offer conditions conducive to a high-quality inspection. Key factors include adequate underwater visibility (water clarity) to identify potential defects, minimal current to ensure diver safety and stable video, and sufficient water depth at a safe anchorage or berth. Inspections are almost always conducted during daylight hours to maximize natural illumination and ensure the most accurate visual assessment.

Vessel Preparation

Proper preparation by the vessel’s operator is crucial for an efficient and successful survey. The vessel must present a reasonably clean hull, as heavy marine fouling can obscure critical inspection areas, welds, and markings. The operator should also provide the dive team with essential documentation, including ship drawings and previous survey reports, to streamline the process. Finally, ensuring safe and clear access for the dive team and their equipment is vital for a timely start. An unprepared vessel is the most common cause of survey delays.

Meeting these strict criteria is fundamental for any in-water survey class approved by a major society. Our expert team manages these complexities so you don’t have to. Confirm your vessel’s eligibility for IWS in Panama.

Why Panama is a Strategic Location for Your In-Water Survey

As a global maritime chokepoint, the Panama Canal is more than a transit point-it is one of the world’s most efficient service hubs. For ship owners and operators, this strategic location eliminates the need for costly route deviations to fulfill regulatory requirements. Vessels can maintain their commercial schedules while completing essential inspections, turning a logistical necessity into a competitive advantage.

Panama Ship Service leverages this unique position by offering comprehensive, class-approved services at both the Pacific and Atlantic anchorages. Our deep local expertise and established procedures ensure a smooth, efficient, and cost-conscious operation every time.

Minimize Deviation and Downtime

In the shipping industry, timing is everything. Instead of diverting to a distant shipyard for dry-docking, your vessel can complete its mandatory in-water survey class approved inspection while waiting for its Panama Canal transit slot. We turn unavoidable waiting periods into productive, compliance-focused activity. Our integrated approach provides a true one-stop-shop for all your vessel’s needs, minimizing complexity and maximizing operational efficiency.

- Zero Route Deviation: Complete surveys along your planned commercial route.

- Productive Waiting Time: Fulfill classification society requirements during Canal transit holds.

- Consolidated Services: Combine your IWS with husbandry, repairs, or MARPOL disposals to further save time.

Favorable Conditions and Expert Teams

A successful survey requires more than just a convenient location. Panama’s designated anchorages provide the suitable underwater conditions-including visibility and calm waters-necessary for high-quality inspections. Our expert diving teams are certified by all major IACS classification societies to perform inspections that meet the most stringent standards. With decades of experience serving vessels at the Canal, our technical proficiency ensures your survey is executed correctly the first time, preventing costly delays or follow-up work.

By choosing Panama Ship Service, you leverage both a premier location and unmatched operational expertise for your next inspection. We are your trusted partner at the Panama Canal, dedicated to providing solutions that save you time and protect your bottom line. Contact our team today to coordinate your next in-water survey class approved and experience the strategic advantage of Panama.

Maximize Uptime with Class-Approved Surveys in Panama

In today’s demanding maritime industry, minimizing downtime and operational costs is critical. As we’ve explored, the in-water survey (IWS) presents a powerful, efficient alternative to traditional dry-docking, allowing you to maintain full compliance without disrupting your vessel’s schedule. Choosing an in-water survey class approved by major IACS members is not just a regulatory formality; it is a strategic business decision that protects your assets and your bottom line.

At Panama Ship Service, our highly experienced and certified diving teams are your trusted partners at the Panama Canal. We deliver meticulous inspections that meet the stringent standards of ABS, DNV, Lloyd’s Register, and more. Our strategic location and expert solutions are designed to provide a seamless, timely, and cost-effective service, ensuring your vessel proceeds with confidence and without unnecessary delays.

Request a Quote for Your Class-Approved In-Water Survey in Panama.

Put your vessel’s compliance in expert hands and keep your operations moving forward.

Frequently Asked Questions About In-Water Surveys

Which classification societies accept In-Water Surveys?

All major IACS (International Association of Classification Societies) members accept In-Water Surveys as a valid alternative to dry-docking under specific conditions. This includes societies such as ABS, DNV, Lloyd’s Register, Bureau Veritas, and ClassNK. Our qualified teams are approved to conduct surveys that meet the stringent requirements of these leading organizations, ensuring your vessel remains compliant without the operational downtime of a shipyard visit. We manage the coordination to guarantee full acceptance.

What is the difference between an IWS and a UWILD survey?

An In-Water Survey (IWS) is performed in lieu of a mandatory dry-docking survey to satisfy a classification society’s requirements for a vessel’s hull. In contrast, an Underwater Inspection in Lieu of Dry-docking (UWILD) is a term more commonly used in the offshore oil and gas industry for mobile offshore units and floating production systems. While the technical execution is similar, the regulatory framework and reporting standards differ based on the asset type and its governing body.

The underlying principle of verifying structural integrity is crucial across many sectors, not just maritime. While on a different scale, the same need to protect a structure from water damage applies to homes. For a look at how experts handle water intrusion below ground level in a residential setting, you can check out Del-Val Basement Waterproofing.

How often can a vessel undergo an IWS instead of dry-docking?

A vessel must typically undergo two dry-docking surveys within a five-year classification cycle. An in-water survey class approved by the society can be used to replace one of these. This allows a vessel to extend its operational window up to 7.5 years between dry-dockings, with the IWS performed around the 2.5-year (intermediate) survey mark. This scheduling provides significant operational flexibility and cost savings for ship owners and charterers, minimizing off-hire time.

What happens if significant damage or defects are found during the survey?

If our certified divers identify significant damage or defects-such as hull breaches, propeller damage, or excessive corrosion-we provide immediate, detailed reporting to the vessel’s superintendent and the attending class surveyor. We document the issue with high-resolution video and still imagery. Our team then works with all stakeholders to develop a timely and cost-effective repair plan, often facilitating in-water repairs to rectify the issue without requiring an emergency dry-docking.

How long does a typical class-approved In-Water Survey take to complete?

A standard class-approved In-Water Survey can typically be completed in 6 to 12 hours. The exact duration depends on the vessel’s size, hull condition, and water visibility. Our expert dive teams operate with maximum efficiency to minimize vessel downtime, often conducting the survey during cargo operations or while at anchorage. We provide a clear operational timeline in advance to ensure seamless integration with your vessel’s schedule and a rapid return to service.

Can propeller polishing or hull cleaning be done at the same time as the IWS?

Absolutely. Combining an IWS with essential maintenance like propeller polishing or hull cleaning is an efficient, cost-conscious solution. Our teams are equipped to perform these services concurrently, maximizing the value of the underwater operation. This integrated approach saves significant time and reduces costs by eliminating the need for separate service calls. We coordinate all activities to ensure the survey and maintenance work are completed without impacting your vessel’s operational schedule.