A critical hydraulic failure at the Panama Canal is not an inconvenience; it is a high-stakes emergency that threatens your transit schedule, budget, and vessel safety. The loss of steering or crane function brings operations to a halt, creating a logistical crisis where every minute of downtime translates into significant financial loss. Finding qualified technicians and sourcing the right components in this critical maritime corridor is a challenge that requires immediate, expert intervention.

As your trusted partner at the Canal, we provide solutions. We are experts in rapid and reliable marine hydraulic system repair, and this guide is designed to give you clarity and control. Here, we cover the most common hydraulic failures, detail our efficient repair process, and share essential preventative maintenance strategies to minimize future risk. Our objective is to get your vessel’s systems back online as quickly as possible, ensuring a reliable repair that prevents delays and keeps your transit on schedule.

The Critical Role of Hydraulic Systems on Modern Vessels

On any modern vessel, hydraulic systems are the indispensable muscle, providing the immense power required for critical operational tasks. These systems operate on proven hydraulic machinery principles, using pressurized, incompressible fluid to multiply force, enabling the movement of multi-ton components with precision and control. This is not a system where performance degradation can be tolerated. A sudden failure translates directly into operational downtime, financial loss, and severe safety risks for the crew and vessel. Proactive maintenance and access to expert marine hydraulic system repair services are therefore fundamental to maximizing a vessel’s uptime and profitability.

Steering Gear Systems

A vessel’s maneuverability is entirely dependent on the reliability of its hydraulic steering gear. Whether using a ram-type or rotary vane system, consistent hydraulic pressure is what allows for precise rudder control, ensuring navigational safety in open seas and confined port waters. Any loss of hydraulic integrity in this system constitutes an emergency, as it directly compromises the vessel’s ability to hold its course or avoid collisions, making swift and effective repair essential.

Deck Machinery and Cranes

From anchoring to cargo handling, hydraulic power drives the most demanding equipment on deck. This includes:

- Winches and Windlasses: For mooring, anchoring, and towing operations.

- Deck Cranes: For lifting cargo, stores, and equipment.

A failure in these systems can halt port operations, leading to costly delays and contractual penalties. The inability to safely anchor or moor a vessel presents an immediate and obvious danger, underscoring the need for a robust approach to marine hydraulic system repair and maintenance.

Hatch Covers and Ramps

For bulk carriers, container ships, and Ro-Ro vessels, hydraulic systems facilitate access to cargo. They power the massive hatch covers and vehicle ramps that are crucial for loading and unloading. A system that fails in the open position exposes valuable cargo to the elements and security threats. A system that fails to open can completely derail a shipping schedule, trapping cargo on board and preventing new loads from being taken on, directly impacting revenue.

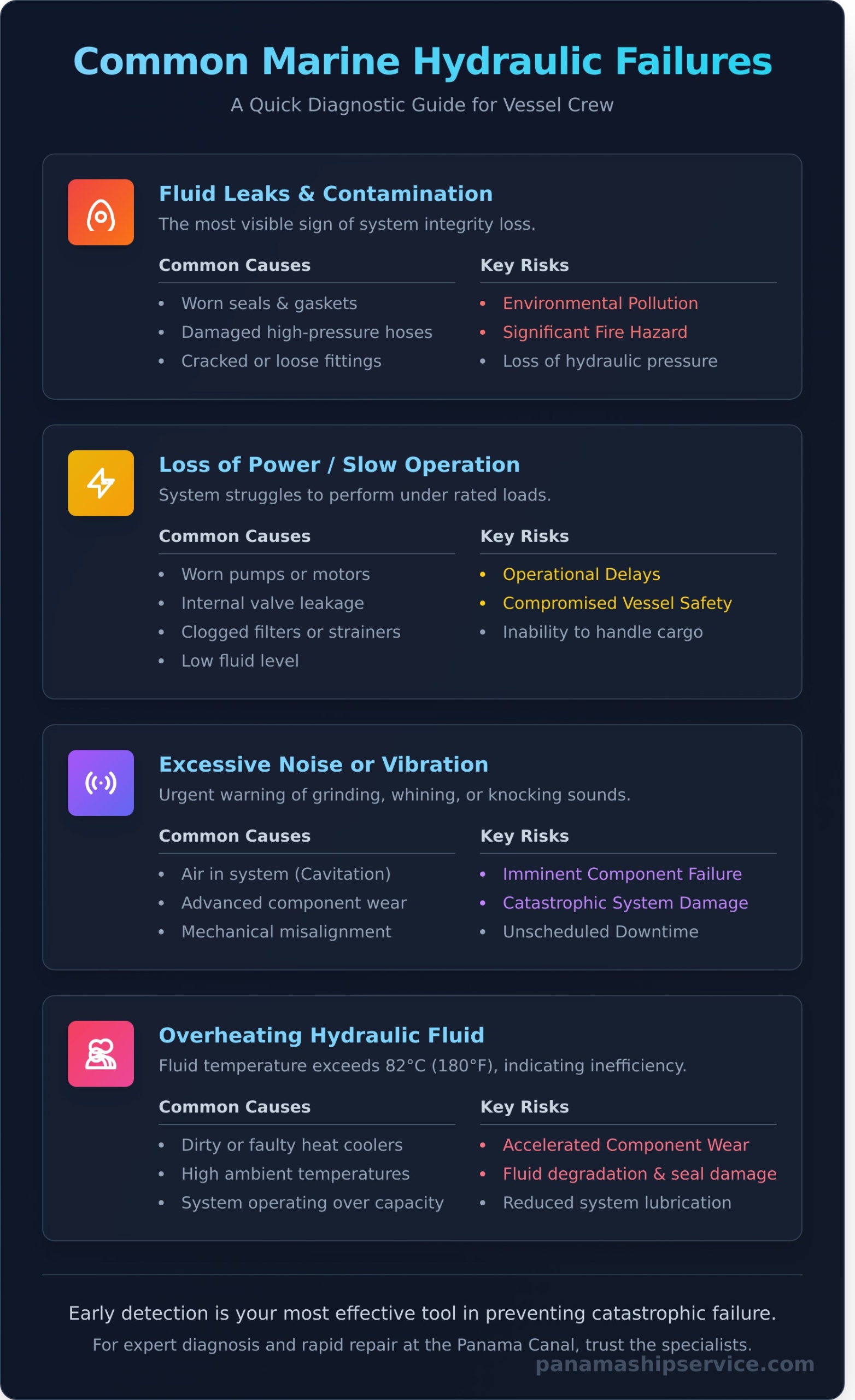

Common Marine Hydraulic Failures: Symptoms, Causes, and Solutions

For a Chief Engineer, identifying hydraulic system issues before they escalate into operational failures is critical. A minor symptom can be the precursor to significant downtime and costly, complex repairs. This practical guide connects common observable symptoms to their root causes, providing the initial diagnostic framework needed to protect your vessel’s machinery and maintain your schedule. Early detection is your most effective tool in preventing catastrophic failure.

Symptom: Fluid Leaks and Contamination

Visible fluid leaks are the most obvious sign of a problem. They are typically caused by worn seals, damaged high-pressure hoses, or cracked fittings. Beyond the loss of hydraulic pressure, leaks pose a severe environmental pollution risk and a significant fire hazard. The solution begins with a systematic inspection to pinpoint the source, followed by the immediate replacement of faulty hoses or a complete seal overhaul by qualified technicians.

Symptom: Loss of Power or Slow Operation

When deck cranes, winches, or steering gear operate sluggishly or fail to handle rated loads, the cause often lies within the system’s core components. Worn pumps, internal valve leaks, clogged filters, or simply low fluid levels can drastically reduce efficiency. This directly impacts operational capability and safety. Initial crew actions should include checking fluid levels and replacing filters, but persistent issues require professional pressure testing and pump performance analysis to diagnose the need for a comprehensive marine hydraulic system repair.

Symptom: Excessive Noise or Vibration

Unusual grinding, whining, or knocking sounds from pumps and motors are urgent warning signs. These are often caused by air entering the system (cavitation), advanced component wear, or mechanical misalignment. Ignoring these symptoms will almost certainly lead to major component failure. While system bleeding can remove trapped air, proper component inspection and alignment must be performed by expert technicians who follow established professional standards for hydraulic system maintenance to ensure long-term reliability.

Symptom: Overheating Hydraulic Fluid

Hydraulic fluid operating above its recommended temperature (typically over 82°C or 180°F) is a sign of inefficiency. Common causes include malfunctioning or dirty heat coolers, high ambient sea or air temperatures, or a system being pushed beyond its design limits. Overheating degrades the fluid, damages seals, and reduces viscosity, leading to poor lubrication and accelerated wear. A thorough inspection and cleaning of coolers and a check of system relief valve settings are crucial first steps.

Our Comprehensive Hydraulic System Repair Process

Downtime is the most significant cost in the maritime industry. Our approach to marine hydraulic system repair is built on a foundation of efficiency, precision, and transparency to get your vessel back to full operational capacity without delay. We follow a systematic, four-step process that ensures every fault is correctly identified, repaired to the highest standard, and rigorously tested. This methodical approach minimizes guesswork and guarantees a reliable, long-lasting solution, keeping your command informed at every stage.

Step 1: Onboard Inspection and Diagnosis

Our qualified technicians board your vessel to conduct a thorough system assessment. We don’t guess; we diagnose. Utilizing specialized equipment, we pinpoint the exact source of the failure, preventing unnecessary work and expense. Our diagnostic toolkit includes:

- Digital pressure gauges and transducers

- Portable flow meters for performance analysis

- Fluid contamination analysis kits

- Thermal imaging cameras to detect overheating components

Step 2: Component Repair and Overhaul

Once the fault is identified, our team executes the most efficient repair strategy. Minor issues like leaking fittings or faulty valves are often repaired in-situ to save time. For major component failures, pumps, motors, and cylinders are removed and taken to our fully equipped workshop for a complete overhaul. We use only OEM or premium-quality equivalent spare parts to ensure the repair meets or exceeds original performance specifications.

Step 3: System Flushing and Fluid Replacement

A component failure often introduces contaminants into the hydraulic circuit, which can cause secondary damage. This critical step is non-negotiable in our process. We use high-velocity flushing rigs to purge all pipework of debris, sludge, and degraded fluid. The system is then refilled with the correct grade of new, clean hydraulic oil, protecting your investment and ensuring system longevity.

Step 4: Pressure Testing and Commissioning

Before handover, we conduct comprehensive testing to validate the repair. The system is brought up to its maximum working pressure in a controlled manner, and all operational parameters are verified against manufacturer specifications. We provide the vessel’s Chief Engineer with a detailed service report outlining the work performed, parts used, and final test results, ensuring complete transparency and a documented service history.

Why Choose Panama Ship Service for Hydraulic Repairs?

At a global maritime crossroads like the Panama Canal, a hydraulic system failure is more than an inconvenience-it’s a high-stakes event that can derail schedules, incur massive costs, and jeopardize your transit slot. In this time-critical environment, you need a partner who operates with precision, speed, and authority. Panama Ship Service is your trusted expert for comprehensive marine hydraulic system repair. We combine a strategic location with deep technical expertise to deliver solutions that maximize your vessel’s uptime. Our capacity as a one-stop-shop for all mechanical repairs means we can manage complex, multi-faceted issues without needing to subcontract, simplifying your logistics and ensuring a single point of accountability.

Rapid Response at the Panama Canal

Timing is everything at the Canal, and we have built our operations around this reality. Our 24/7 rapid-response teams are on constant standby, ready to mobilize the moment we receive your call. This proactive stance means we can often perform essential repairs while your vessel is at the Balboa or Cristobal anchorages, preventing costly delays or the need to go off-hire. We work in direct coordination with your vessel’s agents to ensure every aspect of the service-from personnel boarding to parts delivery-is executed flawlessly and without interrupting your operational flow.

Specialized Expertise and Equipment

Modern marine hydraulic systems are complex, integrated networks that demand specialized knowledge for accurate diagnosis and effective repair. Our technicians are not generalists; they are seasoned specialists in marine hydraulic system repair, with extensive, hands-on experience across a wide range of vessel types and systems. This expertise is backed by the right tools for the job, allowing us to deliver efficient, reliable service directly on board.

- Multi-Brand Proficiency: Our teams are highly skilled in servicing and repairing systems from major manufacturers, including industry leaders like Rexroth, Parker, and Kawasaki.

- Extensive Parts Network: We leverage a robust and reliable supply chain to source genuine spare parts quickly, minimizing downtime while waiting for components.

- Advanced Onboard Diagnostics: We utilize portable diagnostic and repair equipment to troubleshoot issues and perform repairs on-site, getting your systems back online faster.

Don’t let a hydraulic failure compromise your vessel’s schedule. Contact our team for an immediate repair assessment.

Preventative Maintenance: Avoiding Costly Hydraulic Downtime

In the high-stakes maritime industry, unplanned downtime is a critical threat to profitability. Shifting from a reactive to a proactive maintenance strategy is the most effective way to protect your vessel’s operational readiness. Waiting for a component to fail before acting results in emergency repairs, schedule disruptions, and inflated costs. A proactive approach, however, identifies potential issues before they escalate, transforming maintenance from an unpredictable expense into a controlled, strategic investment in uptime.

This philosophy of proactive care extends beyond the maritime world to all critical infrastructure. On land, for instance, the same principles apply to maintaining complex building systems, where specialists such as Plumbing & Boilers London also emphasize preventative maintenance to avoid costly failures.

The majority of hydraulic failures are preventable. Simple, consistent checks and scheduled service can eliminate the root causes of system degradation, such as contamination, fluid breakdown, and component wear. A planned maintenance schedule is not an expense; it is a direct path to saving money and time, ensuring your systems perform reliably when you need them most.

Key Maintenance Tasks

Our expert technicians focus on core preventative measures that deliver maximum impact on system health and longevity. A robust maintenance plan should always include:

- Regular Hydraulic Oil Analysis: Fluid analysis is the most effective diagnostic tool, detecting microscopic contaminants, water ingress, and chemical breakdown long before they cause component damage and require extensive marine hydraulic system repair.

- Scheduled Component Replacement: Proactively replacing filters, seals, and flexible hoses according to manufacturer specifications or operational hours prevents failures from age-related wear and tear.

- Routine System Inspections: Consistent checks for leaks, hose chafing, fluid levels, and operating temperatures are simple yet critical tasks that catch developing problems early.

Developing a Maintenance Plan

An effective maintenance plan is systematic and documented. It begins with adhering to the manufacturer’s recommended service intervals as a baseline. We help clients develop comprehensive plans that include keeping a detailed log of all maintenance, repairs, and inspections, creating an invaluable history for your vessel. Furthermore, training your crew on daily visual inspections empowers them to become the first line of defense against unexpected failures. This disciplined approach minimizes the need for emergency marine hydraulic system repair and ensures your assets remain in peak condition.

Partner with a trusted expert to protect your investment. At Panama Ship Service, we provide the technical support and solutions to keep your operations running smoothly. Ask about our vessel maintenance support services.

Your Trusted Partner for Hydraulic Repairs at the Panama Canal

At the critical juncture of the Panama Canal, a hydraulic system failure can lead to costly delays and operational chaos. The key to a successful transit is twofold: diligent preventative maintenance and access to a rapid, expert response team when issues inevitably arise. Your vessel’s efficiency and profitability depend directly on the reliability of these complex systems and the quality of support you have on the ground.

For over 20 years, Panama Ship Service has provided that essential support. Our certified technicians deliver expert marine hydraulic system repair, backed by 24/7 emergency response teams ready to minimize your downtime. We are the trusted, solution-focused partner that ship owners and charterers rely on to navigate the challenges of the Canal with confidence and efficiency.

Do not let a hydraulic malfunction compromise your schedule. Request an Urgent Quote for Marine Hydraulic Repair and put your vessel in the hands of proven experts. Sail with the assurance that your systems are managed by the best in the business.

Frequently Asked Questions

How quickly can your team respond to an emergency hydraulic failure in Panama?

Our rapid-response teams are strategically positioned to provide emergency service throughout Panama, including at the Canal anchorages. We understand that downtime is costly. Upon receiving your call, our qualified technicians can be dispatched and en route to your vessel within hours. Our objective is to diagnose the failure, propose a time-sensitive solution, and begin work immediately to restore your system’s functionality and keep your transit on schedule.

Can you service and source parts for specific hydraulic brands like Eaton or Danfoss?

Yes, our technicians are highly experienced with all major hydraulic equipment manufacturers, including Eaton, Danfoss, Parker, Bosch Rexroth, and others. We maintain an extensive network of trusted suppliers, both locally and internationally, to source genuine OEM or equivalent parts efficiently. This capability ensures we can perform reliable repairs using the correct components, maintaining your system’s integrity and performance specifications without unnecessary delays.

What information should I provide to get an accurate quote for a hydraulic repair?

To provide a fast and accurate quote, please supply the following: the vessel’s name and location, a detailed description of the problem, and the make and model of the affected hydraulic component (e.g., pump, motor, cylinder). Any available photos or videos of the failure, along with technical drawings or manuals if accessible, are extremely helpful. This information allows our experts to make a precise initial assessment and propose a cost-conscious solution.

Can hydraulic repairs be performed while my vessel is at anchorage?

Absolutely. We specialize in performing comprehensive repairs while your vessel is at anchorage in Panama, on both the Pacific and Atlantic sides. Our mobile teams are fully equipped with the necessary tools and diagnostic equipment to conduct onboard troubleshooting, repairs, and system testing. This service is designed to maximize your operational uptime and avoid the significant costs and delays associated with diverting to a shipyard for repairs.

What are the main differences between marine and industrial hydraulic systems?

Marine hydraulic systems operate in a highly corrosive saltwater environment, requiring specialized materials like stainless steel and corrosion-resistant coatings. They must withstand constant vibration and vessel movement and often use fire-resistant fluids for safety. Furthermore, marine systems are built to meet stringent maritime classification society standards (e.g., DNV, Lloyd’s Register), ensuring reliability in critical offshore conditions where failure is not an option.

How do you ensure the quality and reliability of your hydraulic repairs?

We ensure quality through a multi-layered approach. Every marine hydraulic system repair is performed by our qualified, experienced technicians following manufacturer specifications and maritime best practices. We use only high-quality, genuine or OEM-equivalent parts. After repairs, we conduct rigorous system testing, including pressure tests and operational checks, to verify performance and reliability. Our commitment is to deliver a durable solution that restores your system to peak operational condition.