For any vessel transiting the Panama Canal, operational readiness is paramount. A sudden failure in a critical hydraulic system can lead to catastrophic delays, costly downtime, and significant safety risks. This guide provides a comprehensive overview of marine hydraulic repair, helping you understand the essential systems, recognize warning signs, and know what to expect from a professional repair service, ensuring a safe and efficient passage.

Why Hydraulic Systems Are Critical for Your Vessel’s Operation

Hydraulic systems are the muscular force behind your ship’s most essential machinery, converting fluid pressure into immense power. From navigating narrow channels to handling heavy cargo, these systems must function flawlessly. A system failure doesn’t just halt a single operation; it can compromise the entire vessel’s safety and schedule. Understanding the common issues and prioritizing proactive maintenance, especially before a critical transit like the Panama Canal, is the best way to prevent costly and avoidable downtime.

Common Marine Hydraulic Systems We Repair

Our expert technicians are equipped to diagnose and service the full range of hydraulic equipment found on modern commercial vessels. We specialize in providing rapid, reliable repairs for:

- Steering gear and rudder systems: Essential for maneuverability and safe navigation in congested waters.

- Deck cranes, davits, and lifting equipment: Critical for cargo operations, stores handling, and lifeboat deployment.

- Mooring and anchor windlass winches: Vital for safe berthing, anchoring, and Canal lock operations.

- Hatch covers and ramp door systems: Necessary for protecting cargo and ensuring the watertight integrity of the vessel.

- Bow thrusters and propulsion systems: Key for precise control and docking maneuvers without tug assistance.

Warning Signs of an Impending Hydraulic Failure

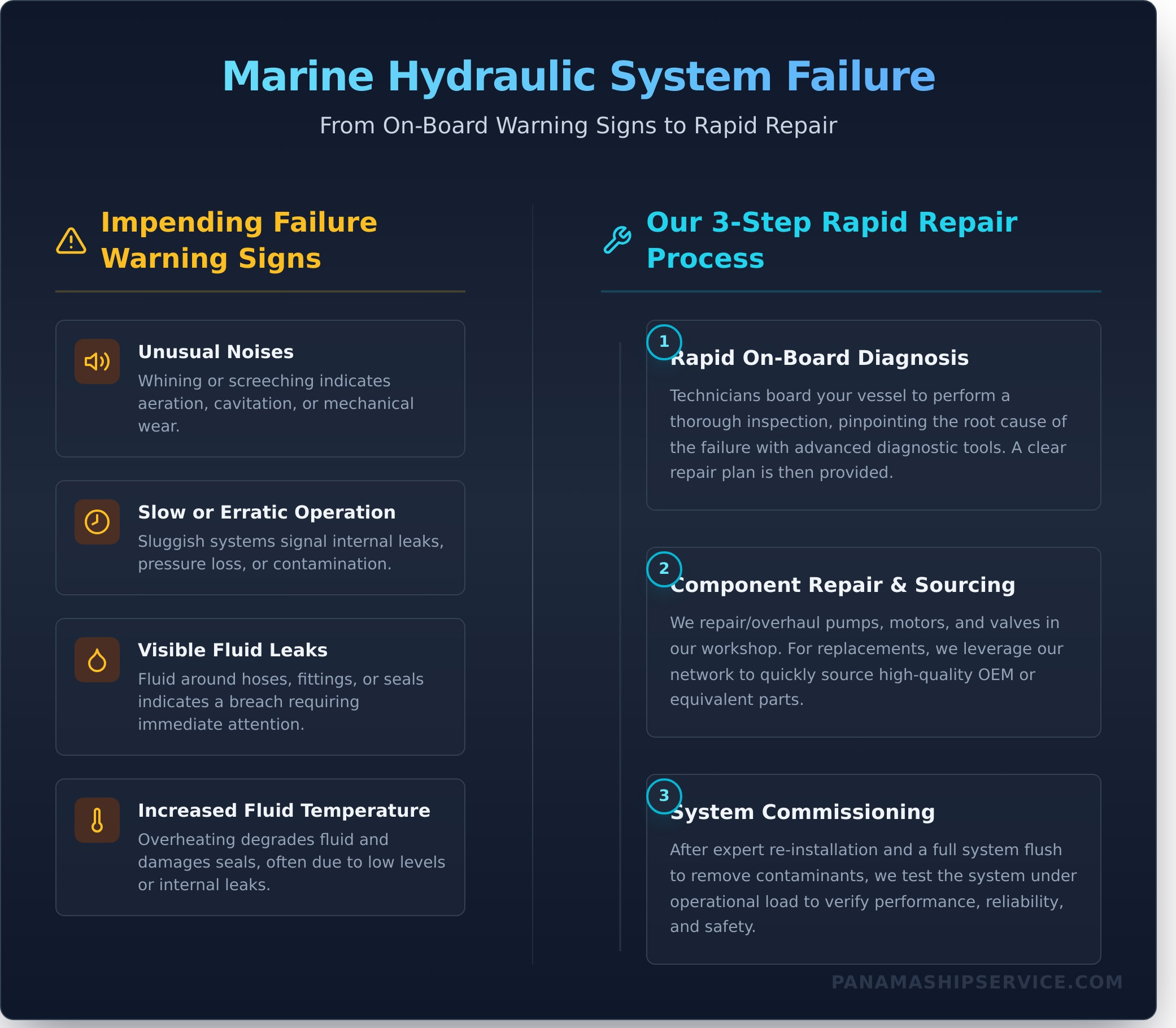

Proactive identification of potential problems can save you from an emergency situation. Train your crew to be vigilant for these common warning signs of hydraulic distress:

- Unusual noises: A sudden whining, screeching, or knocking sound from hydraulic pumps or motors often indicates aeration, cavitation, or mechanical wear.

- Slow or erratic operation: If cranes, winches, or steering systems become sluggish or jerky, it could signal internal leaks, pressure loss, or fluid contamination.

- Visible fluid leaks: Any sign of hydraulic fluid around hoses, fittings, seals, or cylinders is a clear indicator of a breach that needs immediate attention to prevent pressure loss and environmental issues.

- Increased fluid temperature: Overheating is a serious symptom that can degrade hydraulic fluid and damage seals, often caused by low fluid levels, internal leaks, or a failing heat exchanger.

Our Marine Hydraulic Repair Process in Panama

When a failure occurs, time is of the essence. We follow a systematic and transparent repair process designed to deliver quality results with maximum speed. Our primary goal is to restore your vessel’s full operational capability and get you back on schedule without any unnecessary delays. You can expect clear, constant communication from our team at every stage of the repair.

Step 1: Rapid On-Board Diagnosis and Troubleshooting

The first step is accurate identification of the problem. Our technicians will promptly board your vessel, whether at port or anchorage in Panamanian waters. Using advanced diagnostic tools and extensive experience, they perform a thorough inspection to pinpoint the root cause of the failure, not just the symptoms. Following the assessment, we provide a detailed report and a clear, actionable repair plan for your approval.

Step 2: Component Repair, Overhaul, and Sourcing

Once the plan is approved, our team gets to work. We operate a fully equipped workshop capable of handling the repair and overhaul of hydraulic pumps, motors, cylinders, and control valves. For components that require replacement, we leverage our extensive network of suppliers to source high-quality OEM or equivalent spare parts quickly. Every repaired or rebuilt component is rigorously pressure-tested to ensure it meets or exceeds manufacturer specifications before it is cleared for installation.

Step 3: System Installation, Flushing, and Commissioning

The final phase ensures the entire system is restored to peak condition. Our technicians expertly re-install the repaired or new components with precision. We then perform a complete system flushing to remove contaminants, debris, and old fluid, which is crucial for the longevity of the repair. Finally, we commission the system, testing its full range of functions under operational load to verify performance and reliability. Facing a hydraulic issue and need a trusted partner to get you moving? Request immediate assistance.

Why Choose Panama Ship Service for Hydraulic Repairs?

In a location as critical as the Panama Canal, local expertise is your greatest asset. Choosing a local provider means faster response times, a deeper understanding of port logistics, and access to an established network of resources. We understand the immense pressure of maintaining a tight transit schedule, and our entire service is structured to support that urgency. We are more than a vendor; we are your trusted technical partner at the Panama Canal.

Minimize Downtime with 24/7 Emergency Response

Hydraulic failures don’t adhere to a 9-to-5 schedule. That’s why our emergency response team is available 24 hours a day, 7 days a week. Our strategic location in Panama ensures we can quickly dispatch our technicians to your vessel, whether you are at the Port of Balboa or Cristobal. We work efficiently and diligently to execute repairs within the tightest transit schedules, helping you avoid costly delays and penalties.

Certified Technicians and Class-Approved Work

Our team is comprised of highly skilled and certified technicians with extensive experience working on a diverse range of marine hydraulic systems. We are committed to upholding the highest standards of quality and safety in all our work. Every repair is performed in accordance with international standards and can be certified to meet the requirements of all major classification societies, ensuring your vessel remains fully compliant and seaworthy.

Frequently Asked Questions (FAQ)

What are the most common causes of hydraulic system failure on ships?

The most frequent causes are fluid contamination (with water or particles), overheating, failed seals or hoses, and improper fluid levels. Regular maintenance and fluid analysis can prevent a majority of these issues.

How quickly can you respond to an emergency repair request in Panama?

We offer a 24/7 emergency response service. Our team can typically be dispatched to your vessel shortly after your call, ensuring the fastest possible assessment and commencement of repairs.

Can you service specific brands of hydraulic equipment like Bosch Rexroth or Parker?

Yes, our technicians are experienced with all major manufacturers of marine hydraulic equipment, including Bosch Rexroth, Parker, Kawasaki, Eaton, and more. We have the expertise to service and source parts for a wide variety of systems.

Do you carry a stock of common hydraulic spare parts?

We maintain an inventory of common hydraulic components, such as seals, filters, and hoses, to expedite repairs. For specialized parts, we leverage our robust supply chain to source them quickly and efficiently.

What information do I need to provide to get a repair quote?

To provide an accurate quote, please provide the vessel’s name, location, a description of the problem, the type of equipment affected (e.g., crane, steering gear), and the manufacturer and model number if available.

Don’t let a hydraulic failure jeopardize your vessel’s schedule and profitability at the Panama Canal. Trust the local experts who understand the urgency and complexity of marine repairs in this critical waterway. Contact Panama Ship Service today for fast, professional, and reliable solutions. Get a Competitive Quote for Marine Hydraulic Repair and ensure your transit is smooth and successful.